Hygienic Pumps from Michael Smith Engineers

Michael Smith Engineers are a UK distributor of a number of hygienic pump ranges which are suitable for food and drink, pharmaceutical and biotech industries.

| Pump Types | Max Flow Rate | Max Pressure / Head | |

|---|---|---|---|

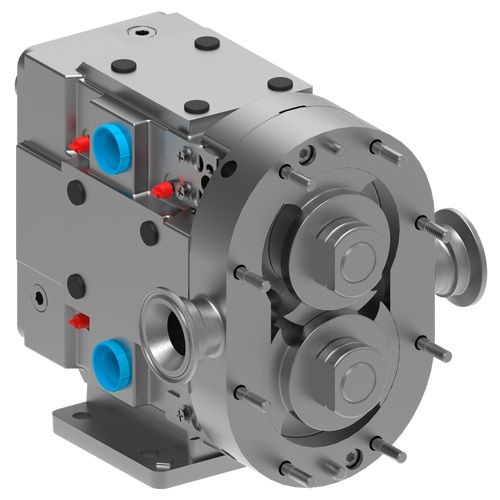

| Viking Hygienic Circumferential Piston Pump | 102 m³/hr | 34 bar | More Info |

| Viking Hygienic Lobe Pump | 189 m³/hr | 15 bar | More Info |

| SAWA Hygienic Centrifugal Pump | 240 m³/hr | 90 metres | More Info |

| SAWA Hygienic Self-Priming Side-Channel Pump | 70 m³/hr | 43 metres | More Info |

| SAWA Hygienic Peripheral Pump | 7 m³/hr | 100 metres | More Info |

| Finish Thompson FDA-approved AODD Pump | 908 l/min | 8.3 bar | More Info |

| Wanner Hydra-Cell Diaphragm Pumps | 138 l/min | 80 bar | More Info |

| HNPM Micro-annular Gear Pump | 1.152 l/min | 60 bar | More Info |

Hygienic pumps are specifically designed and manufactured to the highest specifications to minimize the risk of contamination. This is essential in a number of industries which produce products for human consumption or use such as food, beverages, cosmetics or medicines. Various terms are used to describe hygienic pumps, they are also known as ‘sanitary pumps’. A pump specifically designed for food processing may also be called a ‘food grade pump’. In addition, hygienic pumps can also be described as aseptic or sterile pumps.

Aseptic processing is common in food, beverage and pharmaceutical industries. It is a technique in which a sterile liquid product, such as milk, is packaged (under sterile conditions) directly into a sterilised container using a hygienic pump. A hygienic pump for food processing can take many forms. Pumps for food products such as milk, beer, and wine, may not be suitable for more viscous liquids or liquids with solids such as mayonnaise, pastes, syrups, fruit pulp and vegetable oils. For the latter liquids, the food pump would be more likely to be of a positive displacement design.

In pharmaceutical processes and biotechnology applications, a sterile environment is essential when transporting biological materials such as cell cultures. A sterile pump is one designed with the highest quality components to minimise the risk of contamination in these applications. Sterile pumps for the pharmaceutical industry can also include various aseptic pump technologies.

The internal surface finish of a pump is important, the smoother the finish, the less potential for bacterial growth. Food and beverage applications typically require pump casings electropolished to RA < 0.8 micron finish, whereas pharmaceutical applications can required even finer finishes, to RA < 0.4 microns.

Irrespective of the term used, a pump is considered ‘hygienic’ if it carries certificates of compliance with the appropriate manufacturing and design standards, particularly 3A and EHEDG.

Hygienic pumps are used in a number of industrial applications:

|

Industry |

Application |

|

Food/beverage |

Transferring milk, beer, wine, juices, syrups, meat emulsion etc. |

|

Pharmaceutical |

Manufacturing of drugs, vaccines, and other sterile products. |

|

Cosmetics |

Production of creams, lotions, soaps, and other personal care products. |

|

Biotechnology |

Transferring cell cultures and other biological materials. |

Hygienic pumps are not always required in the food industry. Many processes, by their nature, remain sterile under the chosen operating conditions. For example, chocolate contains a high level of sugar and this inhibits bacterial growth; in fryer systems, the circulation of hot oil maintains a sterile environment. In cases such as these, gear pump such as those from Viking Pump may be suitable. We have supplied numerous Viking gear pumps for chocolate, for pumping sugar syrup and for pumping hot oils.