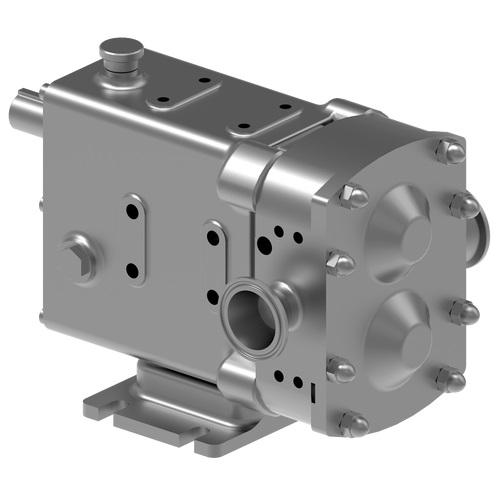

Lobe Pump Overview

Rotary lobe pumps range from industrial designs to sanitary designs. The sanitary designs break down further depending on the service and specific sanitary requirements. These requirements include 3-A, EHEDG, and USDA. The manufacturer can tell you which certifications, if any, their rotary lobe pump meets.

These pumps offer a variety of lobe options including single, bi-wing, tri-lobe, and multi-lobe. Rotary lobe pumps are non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self-priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

How Lobe Pumps Work

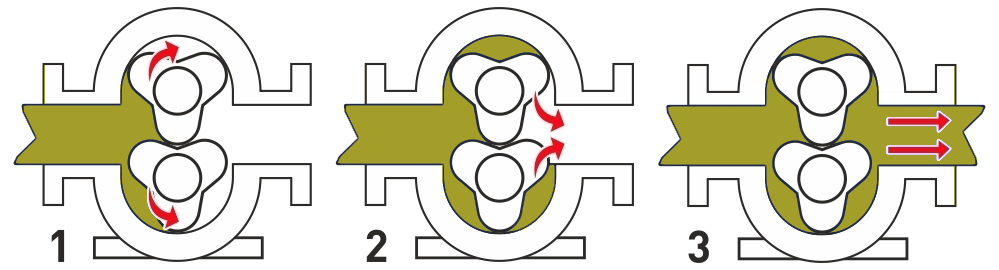

Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

- As the lobes come out of mesh, they create expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the lobes as they rotate.

- Liquid travels around the interior of the casing in the pockets between the lobes and the casing -- it does not pass between the lobes.

- Finally, the meshing of the lobes forces liquid through the outlet port under pressure.

Lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pumps than in other PD types. Since the lobes do not make contact, and clearances are not as close as in other PD pumps, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance. Reductions of 25% of rated speed and lower are common with high viscosity liquids.

Advantages

- Pass medium solids

- No metal-to-metal contact

- Superior CIP/SIP capabilities

- Long term dry run (with lubrication to seals)

- Non-pulsating discharge

Disadvantages

- Requires timing gears

- Requires two seals

- Reduced lift with thin liquids

Applications

Common rotary lobe pump applications include, but are not limited to:

- Polymers

- Paper coatings

- Soaps and surfactants

- Paints and dyes

- Rubber and adhesivesPharmaceuticals

- Food applications (a sample of these is referenced below)

Food and cosmetic products capable of being pumped by lobe rotor pumps.

From Dickenson, T. C. 1995. Pumping Manual, 9th Ed. Elsevier Advanced Technology:

|

Alcohol Apple purée Apricots Baby food Batter Beans Beer Beetroot Biscuit Cream Blackcurrants Brine Broth Butter fat Caramel Castor Oil Cat food Cheese curd Cheese whey Cherries Chicken paste Chili con carne Chocolate Chutney Cockles Coconut oil Cod oil |

Coffee liquor Cordials Corn oil Corn syrup Cottage cheese Cotton seed oil Cranberry juice Cream Cream cheese Custard Dog food Dough Eggs - whole Egg yolk Essences Evaporated milk Fish Flavorings Fondants Fruit juice Fruit pulp Fruit - whole Fruit yogurt Gelatin Gherkins Glucose |

Glycerin Gooseberries Gravy Hand cream Honey Horseradish Ice cream Icings Iodine ointment Jams Jelly Ketchup Lard Liquid sugar Lotions Malt Maple syrup Margarine Marmalade Marshmallow Marzipan Mascara Mayonnaise Milk Mincemeat Molasses |

Mousse Mussels Mustard Nail polish Nail varnish Offal Olive oil Onions Palm oil Pastes Peanut butter Pectin Perfumes Piccalilli Pie fillings Pizza toppings Plasma Potato salad Preserves Purées Quinine Rice pudding Salad dressing Shrimps Soap Solvents |

Sorbitol syrup Soup Soya sauce Spirits Starches Stews Strawberries Sugar Syrup Tapioca Tea Tomato ketchup Tomato paste Tomato purée Toothpaste Vaseline Vegetables Vinegar Water Wines Wort Yeast Yogurt |

Materials of Construction / Configuration Options

- Externals (head, casing) - Typically 316 or 316L stainless steel head and casing

- Externals (gearbox) - Cast iron, stainless steel

- Internals (rotors, shaft) - Typically 316 or 316L stainless steel, nongalling stainless steel

- Shaft Seal - O-rings, component single or double mechanical seals, industry-standard cartridge mechanical seals