We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

Pumps for hot oil fried food production

Why Internal Gear Pumps are the Best Choice for Hot Oil in Food Processing

If you're searching for the best pump for hot oil applications in food manufacturing, the answer is almost always an internal gear pump. These pumps are widely regarded as the most reliable and efficient solution for handling high-temperature cooking oils used in the production of fried foods.

Many of the UK’s top manufacturers of potato crisps, oven chips, potato wedges, and other fried foods and snacks rely on Viking Pump internal gear pumps to keep their production lines running smoothly. These pumps are specifically designed to handle the demanding requirements of hot oil circulation in continuous frying systems.

At Michael Smith Engineers, we have been supplying industrial pumps for hot oil applications for several decades and have years of experience supporting the needs of the food processing industry. We understand the unique challenges these applications present—not just high operating temperatures, but also issues like oil degradation, suspended solids, and the chemical variability of different frying oils.

In continuous production environments, unplanned downtime can be extremely costly. That’s why reliability, durability, and ease of maintenance are critical factors when selecting a hot oil pump. Viking Pump gear pumps meet these requirements, making them the trusted choice for a growing number of UK food processors.

If you’re looking for a hot oil pump solution that maximizes uptime and performance, contact us today to learn more about our range of Viking internal gear pumps for food applications.

|

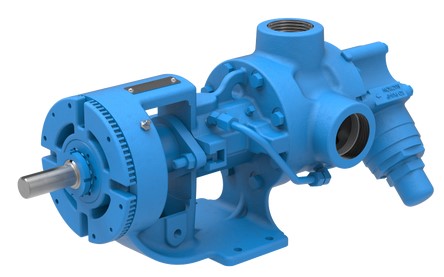

This AK4124A internal gear pump, manufactured by Viking Pump, was one of several supplied to a leading potato crisp producer in Northern England for the circulation of hot sunflower oil. The pump is long-coupled via a gearbox to a 0.75kW, 4-pole motor, delivering a flow rate of 40 LPM at 2 bar. This low operating speed coupled with the robustness and durability of the 4124A series pumps makes them ideal for handling hot oil in potato frying systems. |

|

|

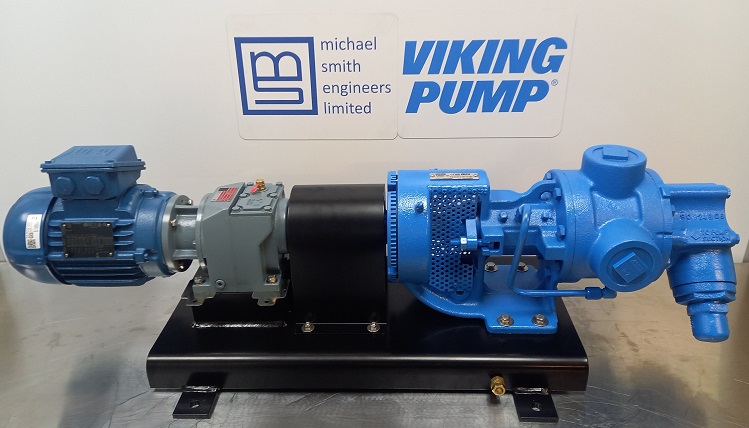

Another AK4124A internal gear pump from Viking Pump, this time supplied with the ports in the ‘V’ configuration. This was done at the request of the customer as the pump will be located underneath a hot oil system at a food production facility. The pump can run bidirectionally to cope with different battch production requirements. Coupled to a 1.1kW motor, the pump can transfer 5 m³/hr of vegetable oil at 180°C. |

|

FAQs: Pumps for Hot Oil Food Frying Applications

Can internal gear pumps be used for pumping hot oil in food frying applications?

Yes, internal gear pumps are especially good for most hot oil transfer in food frying applications, especially where precise flow control is needed.

What are the benefits of using gear pumps for hot oil transfer?

Internal gear pumps have the significant benefit of running more slowly than centrifugal pumps. Typically less than 450 RPM, compared with 1450 or even 2900 RPM for centrifugal pumps. This gives internal gear pumps a far greater working life versus an equivelant centrifugal pump on this application as the wear rate is considerably lower.

Internal gear pumps also offer precise, pulseless flow, can handle high-viscosity oils, and provide high pressure for recirculation loops, making them suitable for controlled oil circulation in fryer systems.

Are centrifugal pumps suitable for hot oil in frying systems?

Yes, centrifugal pumps are commonly used for hot oil transfer in food frying and we do offer suitable stainless steel centrifugal pumps. However, our experience with leading UK producers of fried food products has shown that internal gear pumps are a more reliable and cost effective option.

What is the main difference between internal gear pumps and centrifugal pumps for hot oil?

Internal gear pumps provide constant, precise flow regardless of system pressure, while centrifugal pumps offer high flow at lower pressure, with flow rate varying based on system conditions. Internal gear pumps also operate at much lower speeds and so tend to be more reliable and durable.

What temperatures can internal gear pumps handle in hot oil applications?

The Viking 4124A series internal gear pumps can handle temperatures from -50°C to +230°C and so are more than capable of handling the temperature of hot oil fryers.