We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

Misalignment in Pumps – Possible Causes and Solutions

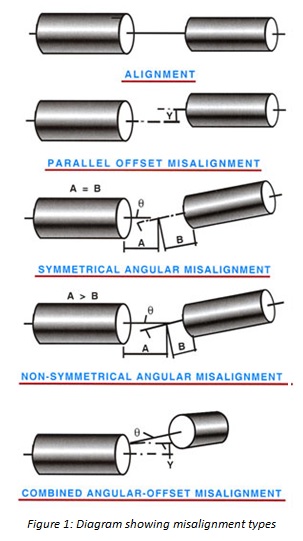

Misalignment occurs when one surface or shaft is forced to deviate from its desired position. Excessive forces and moments can lead to misalignment in several sections of a pumping system. Equally, misalignment can lead to an increase in resultant forces and moments by altering mating surfaces, thereby changing angles and orientations such that new resultant load directions are established.

Issues

Shaft and coupling misalignment is the primary contributing factor in over 50% of plant breakdowns.

Coupling misalignment can result in a build up of heat in bearings from increased friction and vibrations. Consequently bearing life is reduced and in the case of carbon journal bearings lubricated by the pumped liquid; wear can occur elliptically, rapidly reducing functionality. In severe instances, coupling misalignment can lead to fractures in the pump casing, increased noise, and failure of the pump shaft.

Where misalignment exists in coupled shafts, the shafts are forced to rotate in an eccentric manner which increases power consumption and creates vibrations and stresses on the shafts, couplings and machines themselves which ultimately result in breakdowns. Shaft movement can result in fatigue or failure of the shaft, and also reduces mechanical seal life.

Misalignment in piping can occur as a result of incorrect engineering practices. Connecting fixed pipe-work to smaller pumps can increase the chance of misalignment due to a reduced resilience to excessive nozzle loading. Also, sagging from the intrinsic self weight of piping plus the weight of the fluids inside can result in misalignment if the pipe-work is not sufficiently supported.

High temperatures in a pump system can cause pipe-work to expand, the expansion being equal to the coefficient of thermal expansion of the piping material used. This thermal growth can force joints of piping apart, leading to both misalignment and increased nozzle loading.

Solutions

Close coupling is the preferred method of joining pump and motor as it allows a motor to be directly mounted onto a pump. Hence, this technique offers precise alignment and secure hold. Close coupling also provides a compact unit that is often less expensive than an equivalent long coupled assembly. This is because in some cases there is no requirement for a baseplate, while in other applications a small baseplate will suffice.

However, it is not possible to close couple for all applications, specifically those involving high viscosity liquids, high temperature, and high power requirements. For these situations long coupling is used and either a fixed or flexible coupling is chosen.

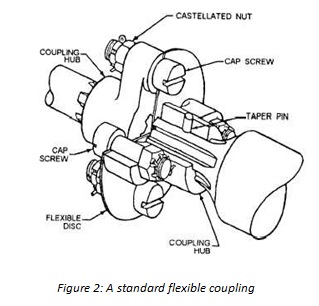

Fixed couplings offer a secure hold however they are more easily misaligned due to their inability to absorb vibrations. Flexible couplings have their own limited tolerance to axial displacement and angular and parallel misalignment, and are therefore the preferred choice for long coupled applications.

Couplings and shafts can be quickly and easily aligned by using a Laser Shaft Alignment (LSA) system. Such systems can align to accuracies of micrometers and therefore help to reduce wear and tear of couplings, seals and bearings. By correcting misalignment LSA aids in minimising energy consumption, reducing noise levels, and lessening vibrations making it a cost-effective technique.

Any rigid pipe-work should be aligned carefully with the pump and also suitably supported throughout the pump system. Inlet piping should be free from any flow disturbing fittings for a given minimum length to reduce potential pressure spikes. Flexible piping should be used where smaller pumps are concerned as they can be particularly intolerant to excessive pipe loads.

Summary

-

Shaft and coupling misalignment is the primary contributing factor in over 50% of plant breakdowns.

-

Coupling misalignment reduces the life of bearings, shafts and mechanical seals.

-

Close coupling offers precise alignment and where possible is the preferred coupling method for eliminating misalignment.

-

When long coupling is required; flexible rather than fixed couplings should be considered.

-

Piping must always be well supported and aligned carefully.

-

Laser shaft alignment is a cost-effective method of negating misalignment issues in a pump system.