We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

Positive Displacement Pumps - when to use them

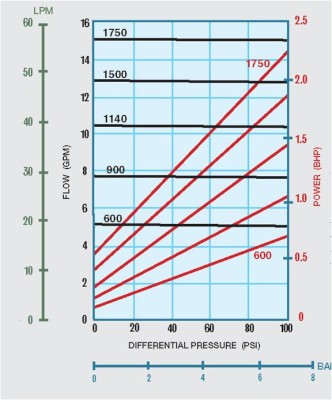

When to use a centrifugal or a positive displacement pump (PD) is not always a clear choice. To make a good choice between these pump types it is important to understand that the two types of pumps behave very differently. By looking at the performance charts below you can see just how different they are. The PD pump (chart A) has more or less constant flow regardless of pressure whereas the centrifugal (chart B) has varying flow depending on the pressure or head.

Another major difference between the pump types is the effect viscosity has on the capacity of the pump. A centrifugal pump loses flow as the viscosity goes up but the PD pump actually increases flow. This is because the higher viscosity liquid fill in the clearances of the pump causing a higher volumetric efficiency. It should also be noted that when there is a viscosity increase there is also greater resistance in the system and so for a given flow, at higher viscosity, the pump will need to generate more pressure.

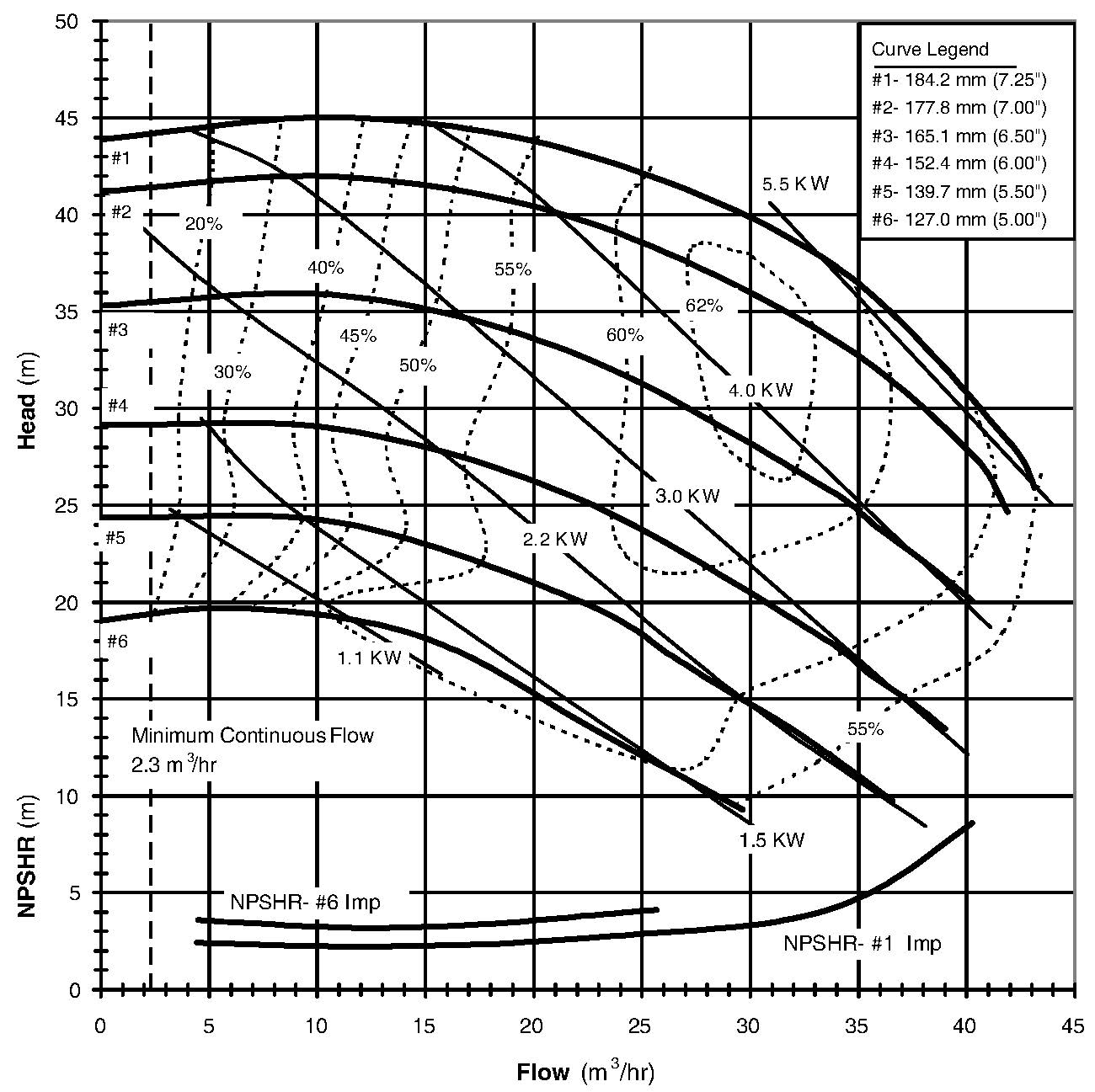

The pumps behave very differently when considering mechanical efficiency as well. By looking at the efficiency plot on chart B you can see the impact of pressure changes on the centrifugal pump’s efficiency. Changes in pressure have little effect on the PD pump efficiency but a dramatic one on the centrifugal.

Another consideration is NPSHr. In a centrifugal, the NPSHr varies as a function of flow, which is determined by pressure. In a PD pump, NPSHr varies as a function of flow which is determined by speed. The lower the speed of a PD pump, the lower the NPSHr.

Another thing to keep in mind when comparing the two types of pumps is that a centrifugal pump does best in the centre of a curve. As you move either to the left or right, additional considerations come into play. If you move far enough to the left or right pump life is reduced due to either shaft deflection or increased cavatation. With a PD pump you can operate the pump on any point of the curve. In fact the volumetric efficiency as a percent actually improves at the high speed part of the curve. This is because the volumetric efficiency is affected by slip, which is essentially constant. At low speed the percentage of slip is higher than at high speed.

-

The most obvious reason to use a PD pump is when you have a high viscosity application. It is common knowledge that a centrifugal becomes very inefficient at even modest viscosity. However, there are many other reasons to select a PD pump over a centrifugal other than high viscosity. In fact PD pumps are very commonly used on thin liquids like ammonia and solvents.

-

A simple rule of thumb is you should consider using a PD pump whenever you might be operating a centrifugal at other than at the Best Efficiency Point (BEP). Of course the further away from the BEP you get the more likely a PD pump will be a better choice. This can typically happen at low flow conditions, modest to high head conditions, or any type of elevated viscosity. As you can see from the efficiency curve it takes more horsepower to operate a centrifugal outside of its BEP. This horsepower has a cost, the initial cost of the larger motor plus a higher life cycle cost in energy consumed. Many times the PD pump will have a lower initial cost as well as a lower operating cost.

-

Another reason to use a PD pump would be if the application has variable pressure conditions. A centrifugal pump will “walk” up and down the curve which can cause process problems. A PD pump will give near constant flow that makes it possible to match the flow to the process requirements. The desire to have constant flow is the reason that a PD pump is the pump of choice for metering applications.

-

Obviously, if there is changing viscosity in the application the PD pump is the best choice. Even a small change in viscosity, like 50-100 cP, has a large impact on the centrifugal.

-

PD pumps generally can produce more pressure than centrifugals. This will depend on the design of each pump but pressures of 20 Bar are not unusual for a PD pump with some models going over 70 Bar. This is a significant difference between the two principles. The capability for a PD pump to produce pressure is so great that some type of system overpressure protection is required.

-

Generally speaking pumps tend to shear liquids more as speed is increased and the centrifugal is a higher speed pump. This makes the PD pump better able to handle shear sensitive liquids. Shear rates in PD pumps vary by design but they are generally low shear devices, especially at low speeds. Internal gear pumps, for example, have been used to pump very shear sensitive liquids. It is important to contact the manufacturer for specific information on shear rates and application recommendations.

-

By their nature, PD pumps create a vacuum on the suction side so they are capable of creating a suction lift. The standard ANSI centrifugal does not create a vacuum so it can not lift liquid into the suction port. There are self-priming centrifugal designs that can lift liquid an average of 15 feet. This corresponds to a vacuum of 330 mm mercury. Wetted PD pumps (a pump that is not full of liquid but with some liquid in it) can often reach vacuums of 630 to 710 mm mercury. So a PD pump is the logical choice when there is a suction lift required.

-

As mentioned earlier, PD pumps tend to run at lower speeds then centrifugals. This will have an impact on seal life, so PD seals tend to last longer than seals in centrifugal pumps. In addition, to assure adequate seal life a centrifugal will typically require one of the seal flush plans. A PD pump, because of its lower shaft speed typically does not need an external flush plan. Also, generally speaking, low speed mechanical devices tend to operate longer than high speed mechanical devices.

-

At certain combinations of flow and pressure centrifugals are inherently inefficient, due to the design of the impeller and the short radius turn the flow must make. These applications are generally under 400 l/min but particularly under 200 l/min. A PD pump, by contrast, is very well suited for low flow conditions. Centrifugals, by contrast, tend to do very well in high flow conditions.

Hopefully, these rules of thumb will make it easier to determine the proper pump principle for your pumping applications.

CHART A

CHART B