We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

Safer, leak-free pumping of challenging liquids with SP mag-drive pumps

14 Jan 2020

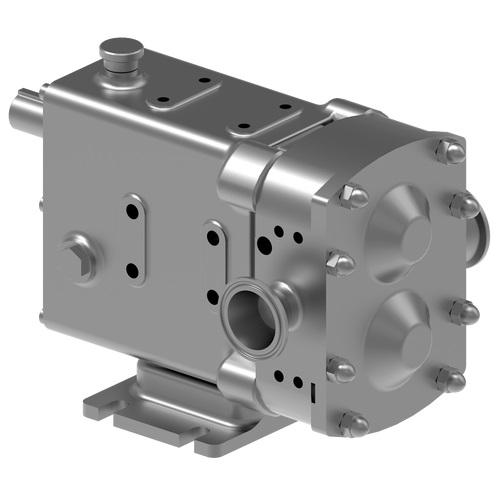

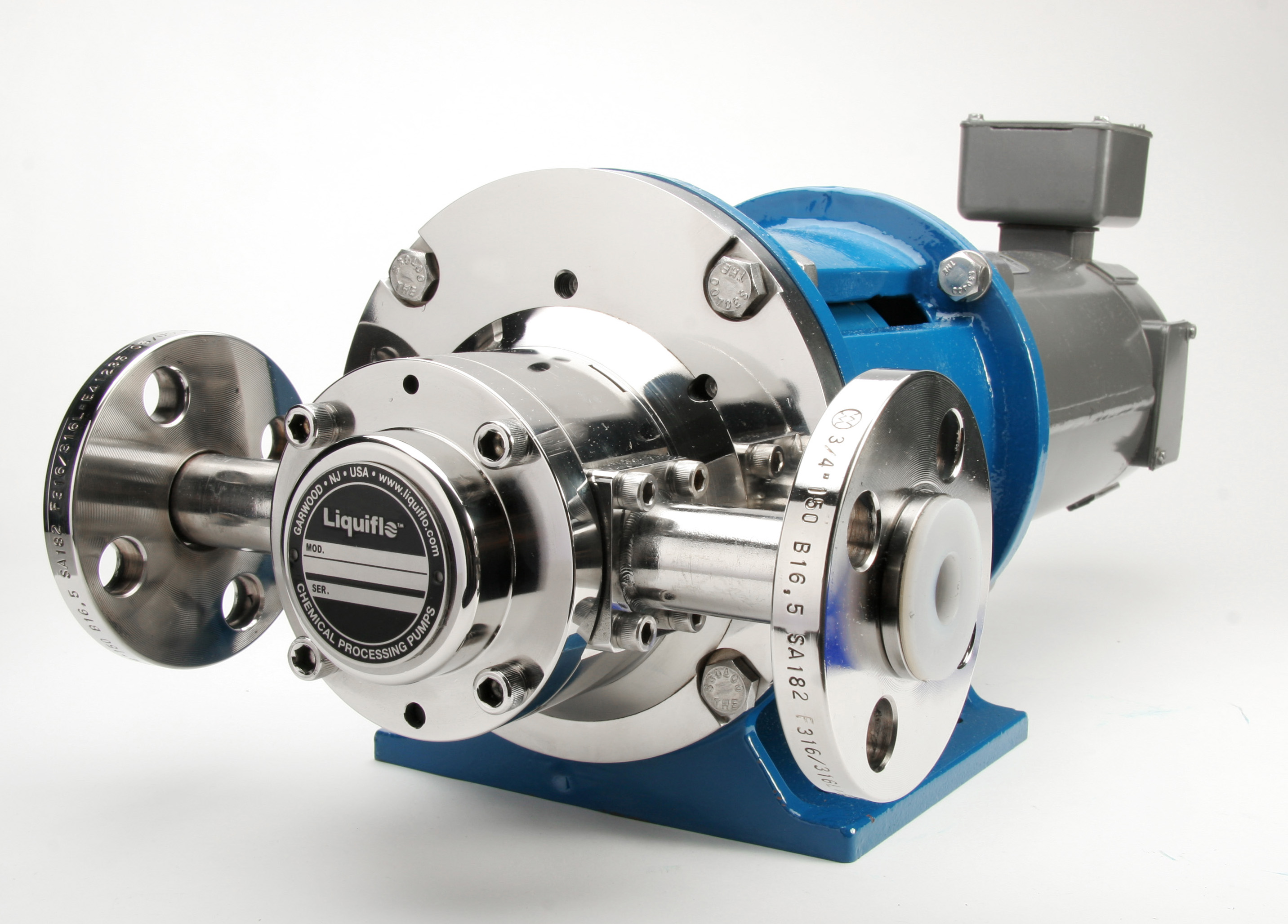

Magnetically driven, self-priming centrifugal pumps are well established as the preferred type of pump for handling aggressive, corrosive and other hazardous liquids thanks to their proven ability for safe, reliable, leak-free and low maintenance operation. A good example of this type of pump is the Finish Thompson SP series of magnetic drive, self-priming centrifugal pumps, available from Michael Smith Engineers (MSE).

For over 40 years, magnetically driven pumps like the FTI SP series supplied by MSE have been successfully pumping difficult liquids in challenging process applications. This is largely due to the key benefit of magnetic drive technology which means no seals to replace and zero leakage, combined with their powerful performance and corrosion-resistant materials for harsh environments.

The range consists of four models providing maximum flow rates up to 45 m3/hr and maximum differential heads to 37 metres. SP self-priming pumps also offer deep lift capabilities (dry lift pumping up to 7.6 metres) and fast priming (5.5 metres in 90 seconds). Another important benefit with SP pumps is that when specified with a carbon bushing they can be run-dry for extended periods without damage, meaning no catastrophic pump failure in the event of a process upset.

In addition to their superior lift capabilities, the SP Series incorporate powerful neodymium magnets allowing them to pump fluids with high specific gravities up to 1.8, such as sulphuric acid, phosphoric acid and sodium and potassium hydroxide.

FTI SP Series pumps are available in a choice of Polypropylene or PVDF which results in a tough and durable, corrosion resistant pump. Maximum operating temperatures are 82°C for the polypropylene version and 104°C for the PVDF version.

They can be mounted to most standard motors, while NPT or BSP threads, adjustable flanges or union connections make it easy to connect to most process systems resulting in reduced installation cost and time.

Typical applications include sump emptying, transferring from underground storage tanks and tanker trucks, pumping in systems that are liable to have trapped or entrained air or in process systems where run-dry protection is needed.

CLICK HERE FOR MORE INFORMATION ON OUR FINISH THOMPSON RANGE OF PUMPS