We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

1224A-ASP series & 1324A-ASP series Cast Iron Asphalt pumps

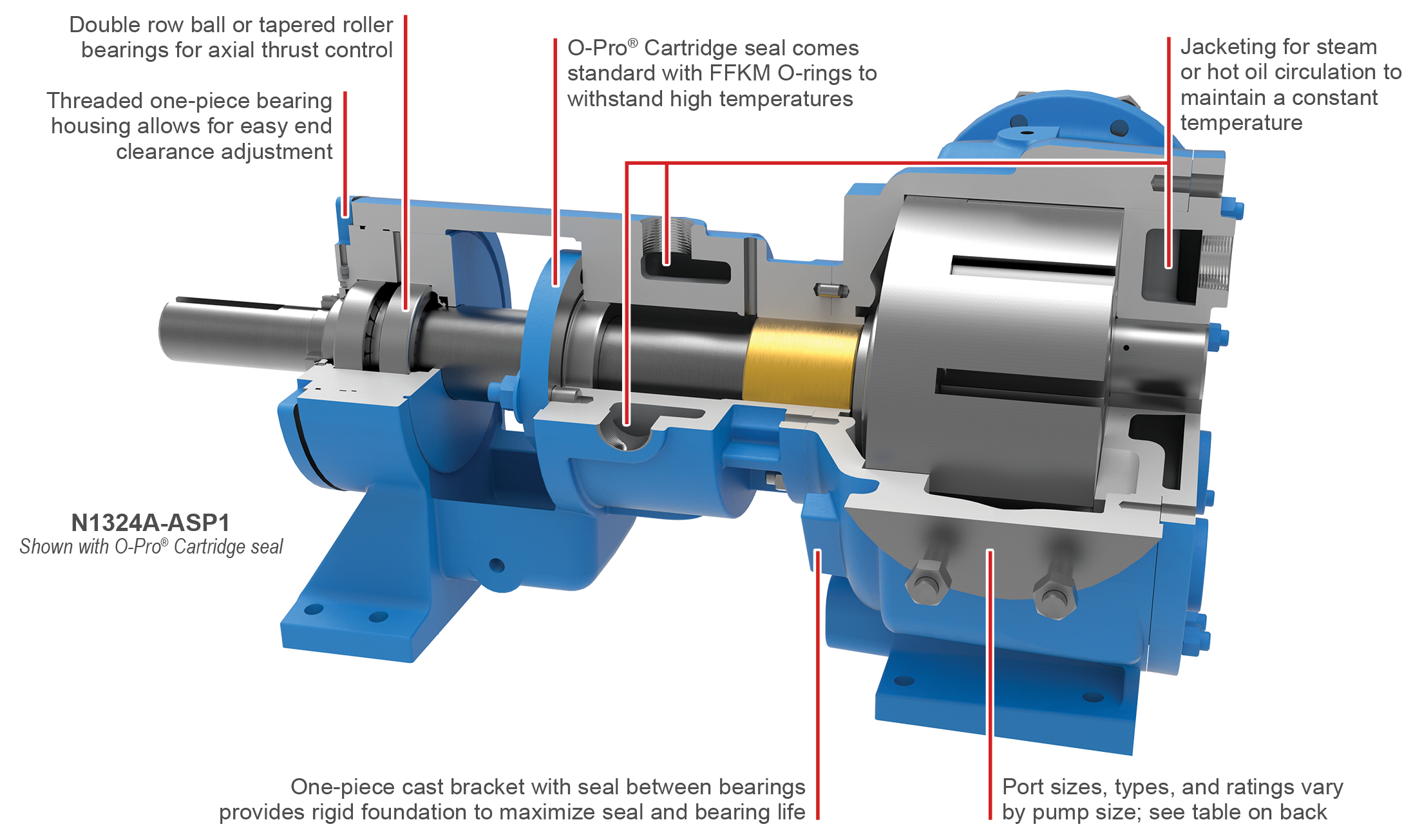

When pumping asphalt and bitumen, pumps have traditionally been sealed with packing, which must continuously leak to stay lubricated. The two series of ASP asphalt pumps from Viking Pump are supplied with Viking's O-Pro Cartridge seal, which uses o-rings in combination with a lubricating grease to provide a robust seal that keeps process fluid from leaking out of the pump. The O-Pro cartridge seal improves operational efficiency by not requiring periodic repacking or re-tensioning of the seal gland, and the leak prevention avoids loss of product and clean up costs.

The 1224A-ASP Series and 1324A-ASP Series Asphalt Pumps are designed specifically for handling asphalts, bitumens, pitch, tar, bunker oils, residual oils and related materials that solidify at ambient temperatures. These asphalt pumps melt ambient-temperature solids to a liquid state prior to pump startup using integral jacketing for steam or hot oil.

The ASP series is offered in two different models:

ASP1 Models:

The ASP1 model asphalt pumps build upon Viking’s proven robust, heavy duty design that has been used for decades of successful asphalt transfer by adding shaft seal leak prevention through use of Viking’s O-Pro Cartridge seal. This patented seal uses a double O-ring design with grease lubrication to provide a robust seal, preventing process fluid from leaking out of the pump. The ASP1 models are best for clean, non-abrasive liquids.

ASP2 Models:

The ASP2 model asphalt pumps are designed for abrasive applications such as the filled asphalts used by manufacturers of asphalt roofing and sealants. These pumps utilize hard parts in key wear areas, combined with unique designs and operating practices to reduce abrasive wear for longest life. These pumps are ideally suited for liquids with concentrations of small but hard particles. The ASP2 model pumps offer shaft seal leak prevention with Viking’s O-Pro Cartridge seal.

FEATURES & BENEFITS

- Positive Displacement Internal Gear pumping principle handles a broad range of viscosities with constant flow rate

- Rugged design provides superior performance in asphalt applications

- Tight clearances offer high efficiency and excellent priming capabilities

- O-Pro Cartridge seal combines reliable sealing with easy maintenance

- Hardened bushings, shaft rotor and idler used in ASP2 model to resist wear in abrasive applications

- Double row ball or tapered roller bearings for axial thrust control

- Threaded one-piece bearing housing allows for easy end clearance adjustment

- O-Pro Cartridge seal comes with FFKM o-rings as standard to withstand high temperatures

- Jacketing for steam or hot oil circulation to maintain a constant temperature

- One piece cast bracket with seal between bearings provides rigid foundation to maximize seal and bearing life

OPERATING RANGE

| SERIES | NOMINAL FLOW | MAXIMUM PRESSURE | TEMPERATURE RANGE | VISCOSITY RANGE | |

|---|---|---|---|---|---|

| m³/hr | Bar | °C | cSt | ||

| 1224A-ASP | ASP1 | 18 - 91 | 14 | -15 to +230 | 20 to 17,000 |

| ASP2 | 5.6 - 41 | 10 | -15 to +230 | 20 to 440,000 | |

| 1324A-ASP | ASP1 | 125 - 340 | 14 | -15 to +230 | 20 to 17,000 |

| ASP2 | 50 - 80 | 9 | -15 to +230 | 20 to 440,000 | |

STANDARD MATERIALS OF CONSTRUCTION

| COMPONENT | STANDARD MATERIAL | |

|---|---|---|

| Casing | Cast Iron, ASTM A48, Class 35B | |

| Head | Cast Iron, ASTM A48, Class 35B | |

| Head Plate | Cast Iron, ASTM A48, Class 35B | |

| Bracket | Cast Iron, ASTM A48, Class 35B | |

| Idler | ASP1 | Cast Iron, ASTM A48, Class 35B |

| ASP2 | Hardened Steel, ASTM A148, Grade 80-40 | |

| Rotor | ASP1 | Cast Iron, ASTM A48, Class 35B |

| ASP2 | Hardened Steel, ASTM A148, Grade 80-40 | |

| Rotor Shaft | ASP1 | Steel, ASTM A108, Grade 1045 |

| ASP2 | Hardened High Strength Steel, ASTM A434, Grade 4140, Class BC | |

| Idler Pin | ASP1 | Hardened Steel, ASTM A108, Grade 1045 |

| ASP2 | Tungsten Carbide | |

| Idler Bushing | ASP1 | Bronze |

| ASP2 | Tungsten Carbide | |

| Bracket Bushing | ASP1 | Bronze |

| ASP2 | Hardened Cast Iron | |

| Pressure Relief Valve | Cast Iron, ASTM A48, Class 35B | |

| O-Pro Cartridge Seal | Stainless Steel, FFKM, Elastomers | |

TYPICAL APPLICATIONS

- Filled Asphalt

- Bitumen

- Polymer Modified Asphalts (PMA)

- Blown Asphalt

- Asphalt Emulsion

- Pitch

- Flux

- Tar

N1324A-ASP1 CUTAWAY IMAGE