We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

Pumps for Dairy Industry

Hygienic, CIP/SIP-Ready Hygienic Pump Solutions

What is the Dairy Industry?

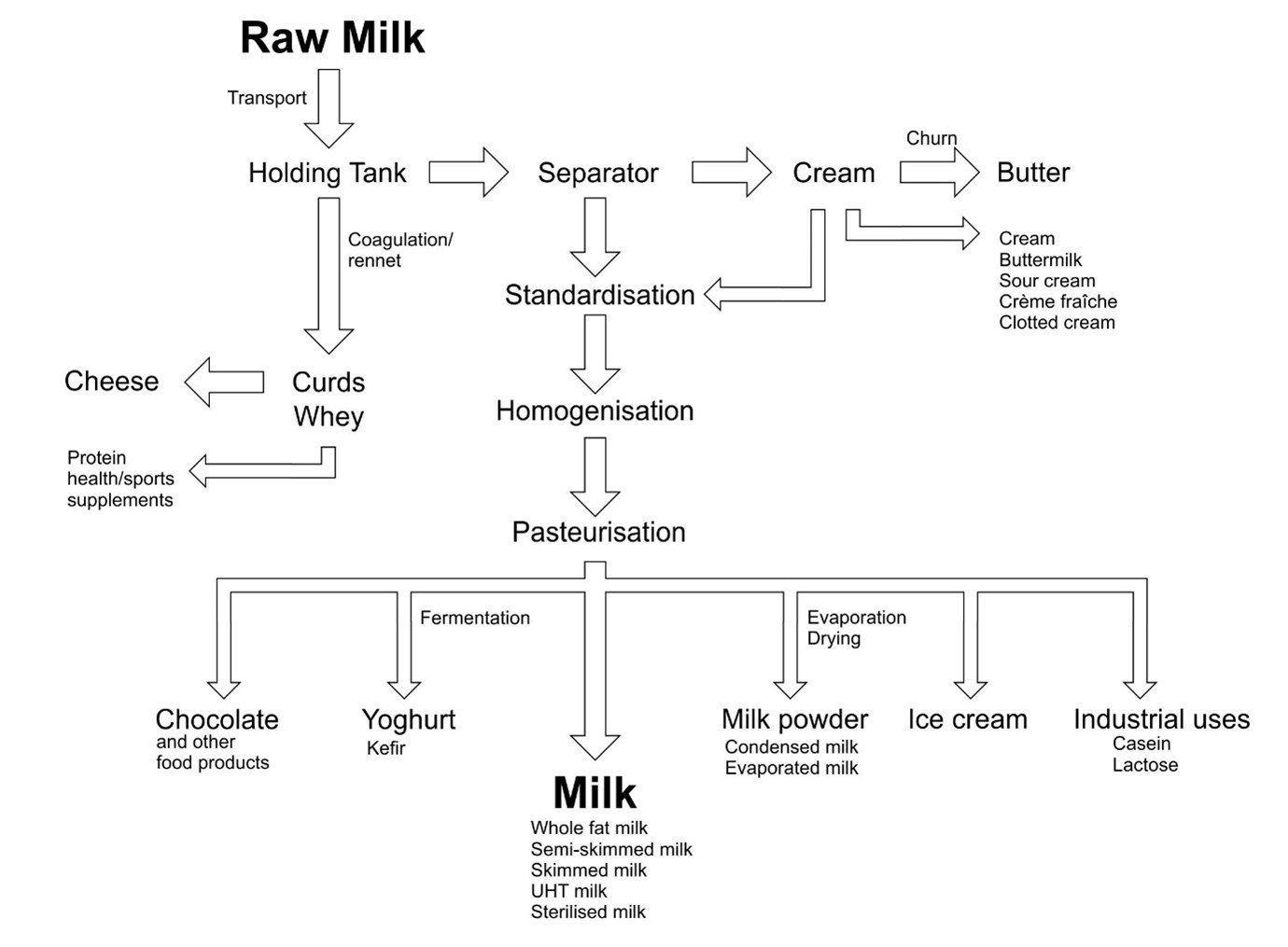

Milk and the many products derived from it have been consumed for thousands of years ever since animals such as cows, sheep and goats became domesticated. Originally farmed locally and on a small scale for immediate use, milk is now collected from farms and transported for industrial processing in centralised facilities. Raw milk is heat treated to extend its shelf life and ensure its safety. Milk is also processed further to make products such as cream, cheese, butter, yoghurt, kefir, ice cream, chocolate and milk powders. Milk and its derivatives are also used as ingredients in many other foodstuffs.

Dairy processes

The dairy industry requires hygienic pumps across its processes due to the potential for microbial growth. Pumps need to be cleanable, with no dead areas that can lead to product contamination. The cleanliness of the internal, product-wetted surfaces should be testable. Note that the pumps and technologies described here are also applicable to the processing of the many plant-based milk alternatives, such as oat, almond, rice and soya milk.

What is a hygienic pump?

Hygienic pumps are specifically designed and manufactured to the highest specifications to minimize the risk of contamination. Various terms are used to describe hygienic pumps. In the US, they are known as ‘sanitary pumps’. A pump specifically designed for food processing may also be called a ‘food grade pump’. In addition, hygienic pumps can also be described as aseptic or sterile pumps. Aseptic processing is common in food, beverage and pharmaceutical industries. It is a technique in which a sterile liquid product, such as milk, is packaged (under sterile conditions) directly into a sterilized container using a hygienic pump.

To maintain high levels of hygiene, pumps and associated equipment must be cleaned regularly. All parts in contact with the transferred media must permit easy and efficient cleaning. This may be specified as CIP (Clean in Place), COP (Clean Out of Place) or SIP (Sanitize/Sterilize in Place) compatible design. CIP is a cleaning technique in which the entire system (including pumps, valves and pipework) can be purged with a cleaning solution without any disassembly. SIP involves steam injection or sterilization. Potentially detrimental effects on seals or other process equipment must be considered. Pumps noted as COP require disassembly for cleaning.

To be classed as hygienic, a pump must have certificates of compliance with the appropriate manufacturing and design standards, particularly 3A and EHEDG.

What types of pumps are suitable for transferring milk?

Milk is a shear-sensitive fluid and its structure and properties can be affected by mixing, stirring, or pumping. The homogenisation process takes advantage of this property by breaking down large fat globules to create a uniform structure and prevent the separation of cream in the final milk product. However, this is a controlled process: shear effects must be avoided in other parts of milk production to avoid compromising product quality.

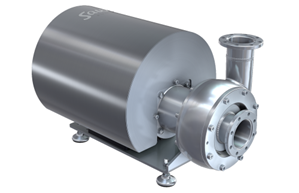

Centrifugal pumps with closed impellers, operating at high speeds can damage milk proteins and so a gentle pumping action combined with the use of open impellers is recommended. SAWA centrifugal pumps, for example, are built with large shaft and casting dimensions and are well suited to evaporator applications, with the impeller design ensuring milk is handled without damage.

Due to milk’s water-like properties, positive displacement pumps are not always the most efficient solution. Bornemann's twin screw design provides the benefits of a non-contacting rotary positive displacement pumping principle combined with efficiencies that can equal centrifugal pumps on water-like products. The pumps can handle inclusions and thin liquids with high efficiencies. They can also transport low viscosity cleaning liquids such as water, detergents or cleaning liquids. This means that an additional pump is not required for CIP cleaning.

SAWA LE centrifugal pump: hygienic design and CIP and SIP capable

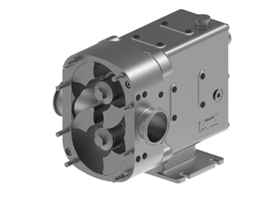

Cutaway view of Bornemann Hygienic Twin Screw pump SLH-5G

Bornemann and SAWA pumps have DIN 11851 threaded connections which is the dairy standard. This means pumps are available on a shorter lead time and easy to integrate into existing systems. All other common connection types (threaded: DIN 11864-1/RJT/SMS; flanged: DIN 11864-2/DIN/ANSI; clamped: DIN 11864-3/tri-clamp) are also available.

What pumps are suitable for cream and yoghurt?

Across MSE’s hygienic pump range, a number of pumps have been designed to hygienic standards and accredited by recognised bodies. They are fully compatible with industry standard cleaning protocols (COP and CIP) and sterilization (SIP) described above.

Our hygienic pump range are suited for specialist, challenging applications in creameries and yoghurt factories, where the benefits of non-contacting rotary positive displacement pumps are self-evident due to products with high viscosities and even greater importance of low shear product handling. For example, Viking Pump Hygienic circumferential piston pumps, due to their operating principle and rotor design, are ideal for handling soft solids such as curds.

Bornemann hygienic twin screws are perfectly suited for conveying soft solids such as fruit pieces used in yoghurt production.

Viking’s Revolution® Series is a circumferential piston pump design with excellent suction capability. Bi-wing rotors allow gentle handling of soft solids.

Which pumps are suitable for plant-based ‘milk’ production?

The starting feedstocks for plant-based milks (oat, soya, almond, rice) are generally thick, viscous, and shear-sensitive slurries which require considerable processing, particularly homogenisation, to give an emulsion with the necessary ‘milk-like’ texture and consistency. The transfer of these slurries requires low shear, positive displacement pumps such as rotary lobe or twin screw pumps.

Following homogenisation, the resulting ‘milks’ are shear-sensitive low-viscosity (thin) liquids that require hygienic pumps similar to those already described. In addition, accurate dosing pumps (peristaltic or gear pumps) are needed to introduce flavours, colourings and vitamin additives into the final product.

Pumps for CIP Delivery and Return

As noted above, cleaning of dairy installations is critical. CIP systems, where hot water and chemicals are induced to flow through pumps, pipework and associated items at a sufficient velocity and pressure to ensure all product-wetted surfaces are cleaned, are commonly integrated. These systems require specialist pumps for delivery and return/scavenge. These pumps should also be hygienic and service friendly. SAWA LE centrifugal pumps deliver high flow rates and have a long service life due to their robust design. SAWA HD liquid ring pumps and SAWA LES hybrid centrifugal pumps are self-priming designs that can handle high amounts of gas and as such are ideal for the completely emptying tanks and pipework of water after a CIP cleaning cycle.

What options and accessories are available?

A full array of installation options are available for MSE’s hygienic pump range, including bespoke baseplates and trolleys, gearboxes, motors and speed controls, drain valves, and seal support systems. We can also provide industry specific testing and documentation such as FDA, USP CL6 and ADI-free certificates for elastomers, 3.1 material certificates for metallic components and surface finishing, and multiple duty point testing and noise testing.

Summary

SAWA, Viking Pump Hygienic, and Bornemann pumps are widely used in the dairy industry, with pump configurations designed to ensure process compatibility, reliability, and long service life. Michael Smith Engineers supports these brands with OEM spare parts and manufacturer-accredited workshop capability for off-site servicing.