We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

Pumps for Chocolate Production

Introduction to Chocolate Processing

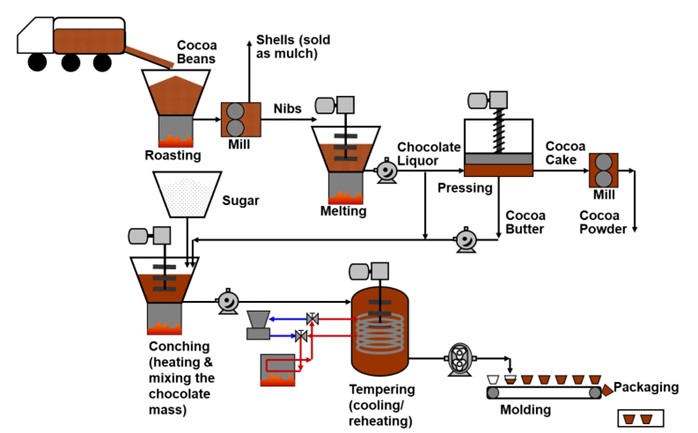

Chocolate manufacturing is a complex, multistage process—from cocoa farming to creating confectionery products. After fermentation and drying, cocoa beans are roasted, cracked, and milled into chocolate liquor. Key ingredients—cocoa butter, chocolate liquor, and cocoa powder—are combined with sugar, milk (dairy or plant based), and emulsifiers to produce various types of chocolate.

The chocolate manufacturing process (© Viking Pump)

Pumps are required in many of the steps in chocolate manufacture. In particular, they are used to move chocolate liquor and cocoa butter to and from trucks and storage tanks, to transfer to day tanks, to supply mixers and tempering machines, recirculate chocolate in enrobing machines, and to feed moulds. Pumps are also required to supply and dose additional ingredients such as milk, flavourings and emulsifiers.

Challenges of Pumping Chocolate

Chocolate feeds are highly viscous, abrasive, and shear-sensitive. Pumping must be done at controlled temperatures to maintain liquidity without burning the product. Pump failures often stem from seal issues, product separation, or high shear. Selecting the correct pump type and seal is critical to minimizing downtime and maintaining product integrity.

Criteria to consider when selecting a pump for chocolate applications?

- Viscosity

- Solids

- Temperature

- Cleaning

- Maintenance

- Food safety compliance

Centrifugal pumps, which are preferred in many industrial and manufacturing processes, are unsuitable for chocolate processing. They are less efficient with viscous fluids and their high speed of operation could cause shear damage. A number of different positive displacement pump technologies are preferred because of their gentle action, efficiency with viscous fluids and ability to control delivery rates precisely. However, centrifugal pumps are used for CIP Feed and Scavenge/Return applications for hygienic installations.

Pump Technologies for Chocolate Manufacturing

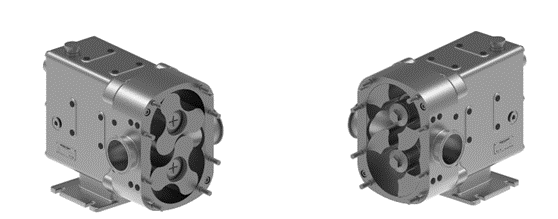

Rotary Lobe and Circumferential Piston Pumps

Rotary lobe pumps and circumferential piston pumps share similar technology, but have some important differences. They are very popular for hygienic applications and offer a smooth, non-pulsating, low shear flow which is ideal for pumping shear-sensitive chocolate. Both types of pump are used extensively in food, beverage, and dairy industries because of their gentle action on shear-sensitive liquids and ability to handle solids.

Their stainless steel, sanitary designs meet hygienic design standards (such as EHEDG and 3A) and food safety regulations (such as FDA and EN1935). The timed rotors do not contact each other, making them suitable for handling solids like fruit or nuts.

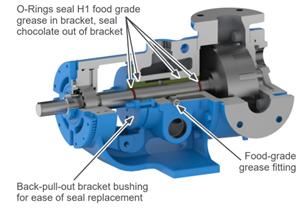

Internal Gear Pumps

Gear pumps use the actions of rotating cogs or gears to transfer fluids. The rotating element develops a liquid seal with the pump casing and creates suction at the pump inlet. Fluid, drawn into the pump, is enclosed within the cavities of its rotating gears and transferred to the discharge. There are two basic designs of gear pump: external and internal. Internal gear pumps are preferred for chocolate processing because of their simpler design.

Preferred for chocolate liquor and cocoa butter due to their robust design and single-shaft and sealing area configuration. Viking’s 1224A-CHC1 and CHC2 models offer jacketed cast iron construction and innovative O-Pro barrier seals to reduce leakage and prevent clogging. FDA- and EC1935/2004-compliant materials are offered as standard.

Twin Screw Pumps

A twin screw pump comprises of two, parallel, intermeshed screws. With the synchronised rotation of the two screws, cavities are created along the pump’s axis and these allow the transfer of the pumped medium from suction to discharge in a controlled, non-pulsating flow. To reduce wear and corrosion, the construction usually involves high grade materials, polished surface finishes, wear hardening, and carefully machined internal tolerances that allow for shaft deviation in high pressure applications.

The pumps are ideal for hygienic applications, allow easy disassembly and cleaning, are self-draining, and have the advantages of being non-contacting, having flushed seals and external gearings and bearings, isolated from the process end of the pump. Efficianct is maintained even with low viscosity fluids, so the same pump can be used for both the process and cleaning cycles and the flow can be reversed to avoid product wastage before a cleaning cycle.

Twin screw pumps are more complex and potentially more expensive than lobe or gear pumps.

Diaphragm Pumps

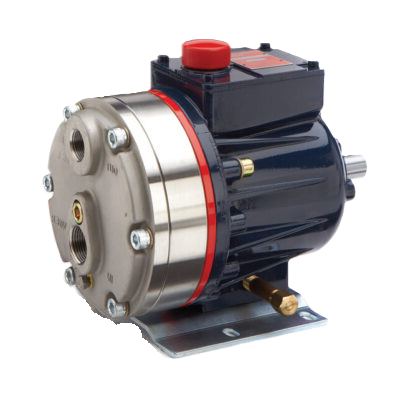

Diaphragm pumps, like the Wanner Hydra-Cell pumps, use multiple diaphragms to achieve steady flow. Their non-rotating design reduces shear and eliminates shaft seals. Suitable for dosing and metering additives or ingredients.

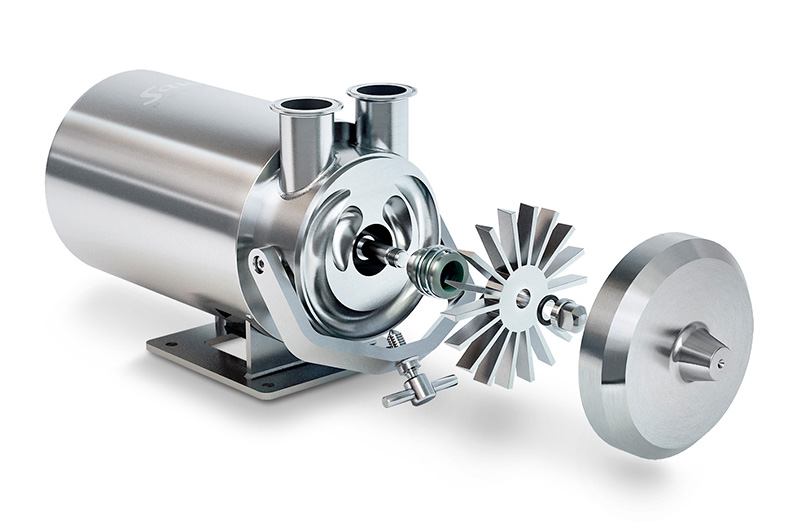

Side Channel Pumps

Side channel pumps offer quiet operation with good handling of fluids like milk. CIP- and SIP-compliant versions such as the Sawa HD ensure hygienic standards are met with minimal dead space. These pumps are also used for CIP Scavenge/Return applications as they can handle high amounts of air and completely drain down tanks and pipework.

Material Selection: Stainless Steel vs. Cast Iron

For upstream chocolate handling, cast iron is acceptable due to the low risk of microbial growth. However, milk-containing products require stainless steel pumps that meet strict hygiene standards. Ease of cleaning and food safety certification are essential in these applications.

Although food-grade pumps are safe for use in throughout the chocolate pumping process, fully ‘hygienic’ pumps are not always required. Many processes, by their nature, remain sterile under typical operating conditions. Chocolate contains a high level of sugar and this inhibits bacterial growth. However, pumps for milk and milk-containing feeds need to satisfy strict hygiene standards (FDA, 3-A Sanitary Standards and EHEDG (European Hygienic Engineering & Design Group)), be made of food grade materials such as stainless steel, and be easy to clean without causing major process shutdowns.

Summary

Chocolate production requires careful pump selection due to challenges such as high viscosity, shear sensitivity, and temperature control. Gear, lobe, piston, and twin screw pumps are suitable depending on hygiene requirements and the part of the process. Appropriate sealing technology, with material compliance with FDA and hygienic are key to system reliability.

Why Choose Michael Smith Engineers?

With extensive experience in food-grade and hygienic pump technologies, Michael Smith Engineers can help you select the right pump for your chocolate production needs. We are the sole UK distributor for Viking Pump gear pumps, Bornemann hygienic twin screw pumps and SAWA hygienic, as well as representing Viking Pump Hygienic and Wanner Hydra-Cell. Contact us for tailored support.