We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

G Series Pumps

- Overview

- Features & Benefits

- Specifications

- Other Info

- Case Studies

Overview

The simple design of the Hydra-Cell Industrial pumps make them durable and able to handle the fluids that can destroy other pumps. These positive displacement pumps give smooth, near pulse free output accurately, reliably and repeatedly.

Hydra-Cell pumps are equally suited to high and low pressure applications. They are highly efficient, heavy-duty pumps for liquid transfer, metering and dosing, injection and spraying of the widest range of liquids.

Hydra-Cell seal-less diaphragm pumps can handle corrosive, non-lubricating and abrasive liquids and slurries and can even run dry without damage.

The range covers flows between 0.4 to 248 l/min at maximum discharge pressures between 20 and 170 bar, depending on the model and materials of construction.

Hydra-Cell Pumps Seal-Less Design Advantages

Hydra-cell positive displacement diaphragm pumps feature a hermetically sealed pumping chamber so there are no mechanical seals, packing or cups to leak or replace. This seal-less design coupled with the use of check valves in the pump head enable Hydra-Cell to pump abrasives and particulates that would damage other types of pumps. Also Hydra-Cell can run dry indefinitely without damage to the pump and the multiple diaphragm design ensures virtually pulse-less, linear flow without the need for pulsation dampeners.

Economical

-

Can save approximately 30% to 50% on purchase costs because Hydra-Cell uses lower kilowatt motors to achieve the same flow rates and pressures as other pumps.

-

Compact design has a smaller footprint allowing more efficient use of floor space.

-

Operates at 85-90% energy efficiency to reduce operating costs.

-

Hermetically sealed design reduces maintenance and repair costs and minimizes the cost of spare parts compared to other types of pumps.

Versatile

-

Variety of styles and models to pump a wide range of flows and discharge pressures.

-

Hydraulically-balanced diaphragms can pump low to high viscosity liquids through the complete pump pressure range.

-

Available in a wide variety of wetted construction materials to meet a broad range of applications and ensure extended pump life even when handling corrosive and aggressive liquids.

-

Can be supplied with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts.

-

ATEX certification available or other certification for specific applications or to meet international standards.

-

Design allows for simple exchange of pump head materials and can accommodate mixing different materials with one pump head.

Capable

-

Hydra-Cell can pump abrasive solids and particulate matter up to 800 microns (depending on pump model) and 9 hardness (Mohs) without the need for fine filtration.

-

Multiple diaphragm design gives virtually pulse free flow that exceeds API 675 standards for accuracy, linearity and repeatability.

-

Low-shear pumping action protects the integrity of long-chain structures.

Reliable

-

Hydra-Cell can dry run without damage.

-

Robust design allows operation even in difficult operating conditions.

-

Hermetically sealed - no mechanical seals, packing or cups to leak or replace.

-

Up to 6,000 hours between lubricating oil changes.

-

Hydra-Cell have experience of pumping acids, slurries and liquids containing up to 40% of non-dissolved solids.

-

The design ensures the pumped fluid is not used for internal lubrication of the pump

-

No tight tolerances in the pump head which can be prone to corrosion or solid particles.

Environmental

-

Liquids are hermetically sealed from the atmosphere - no leak path for toxic vapours or harmful gasses.

-

No dynamic seals to leak any volatile organic compounds (VOC).

-

Hydra-Cell pumps have high hydraulic efficiency - lower energy costs to operate pump.

Hydra-Cell Fluid Handling Capability

Handles Abrasives and Low-to-High Viscosity Fluids

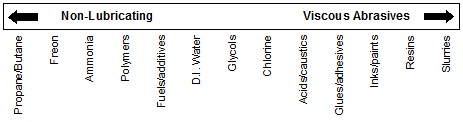

From drinking water to highly viscous cutting fluids, Hydra-Cell multiple diaphragm pumps can handle the full spectrum of process fluids while maintaining high efficiency operation. These can include non-lubricating fluids as well as difficult fluids with abrasives that can damage or destroy other types of pumps. This makes Hydra-Cell an ideal choice in a wide range of industries and when serving multiple applications in one facility.

Hydra-Cell Primary Pumping Applications

|

|

|

|

Markets and Industries Served

|

|

| Hydra-Cell wobble plate design principle |

|---|

| Hydra-Cell crank shaft design principle |

| Explanation of the Hydra-Cell patented Kel-Cell technology |

| Common wetted materials used in Hydra-Cell pump |