We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

Chemical Pumps & Chemical Transfer Pumps

Safe Chemical Pumping: The Right Chemical Pump for Your Liquid

Chemical pumps are essential for the safe, efficient transfer and dosing of a wide range of corrosive and aggressive chemicals in industrial and laboratory environments. At Michael Smith Engineers, we offer an extensive selection of high-quality pumps designed to handle acids, alkalis, solvents, and other hazardous liquids with precision and reliability.

Whether you require a chemical transfer pump for the bulk movement of chemicals or a dosing pump for accurate chemical injection, our expert team can help you select the most suitable pump for your requirements.

We distribute magnetic drive pumps, air-operated double diaphragm (AODD) pumps, peristaltic pumps, and other chemical-resistant pumps to meet these demanding process requirements.

With over 50 years of experience as trusted chemical pump suppliers in the UK, we provide tailored advice, technical support, and reliable after-sales service to keep your processes running smoothly and safely. Explore our range below, or contact our engineers today for guidance on selecting the right pump solution for your specific needs.

Our chemical pump range

Our ranges of pumps for the transfer of chemicals include:-

- Plastic pumps

- Mag drive pumps

- AODD chemical pumps

- Internal and external gear pumps

- ETFE lined pumps

- Metering pumps

- Dosing pumps

| Our Pump Ranges | Flow Range | Max Pressure | |

|---|---|---|---|

| DB Series Polypropylene and PVDF Centrifugal Pumps | Up to 50 m³/hr | 43 metres | More Info |

| UC Series ETFE Lined Centrifugal Pumps | Up to 329 m³/hr | 102 metres | More Info |

| AC Series Metallic Conventionally Sealed Centrifugal Pumps | Up to 58 m³/hr | 53 metres | More Info |

| Dickow Single Stage Centrifugal Pumps | Up to 800 m³/hr | 150 metres | More Info |

| Wanner High Pressure Diaphragm Pumps | Up to 595 l/min | 345 bar | More Info |

| Metallic Gear Pumps | Up to 345 m³/hr | 172 bar | More Info |

| Dickow Multistage Centrifugal Pumps | Up to 500 m³/hr | 400 metres | More Info |

| Dickow Side Channel Pumps | Up to 50 m³/hr | 400 metres | More Info |

| Dickow Peripheral Pumps | Up to 17 m³/hr | 400 metres | More Info |

| Viking Vane Pumps | Up to 36 m³/hr | 14 bar | More Info |

| Codip PTFE Tubular Diaphragm Pumps | 20 to 300 l/min | 10 bar | More Info |

| FTI Air Operated Double Diaphragm Pump | Up to 54 m³/hr | Up to 8.3 bar | More Info |

Michael Smith Engineers are acknowledged experts in the selection of pumps for all types of chemical applications. As an experienced pump distributor, we have over half a century of experience of choosing the correct pump technology, the correct pump material and the correct pump size for the chemical being pumped.

Chemical Pump Solutions for Different Applications

Alkalis and Caustic Compounds

Caustic materials such as sodium hydroxide (caustic soda), potassium hydroxide and calcium oxide (quicklime) are used in a wide range of industries. Some chemicals used as refrigerants can be harmful, such as ammonia. For pumping these materials, it is essential that the correct pump material and pump type is chosen to avoid premature corrosion and potential dangerous leakage.

Acids

Choosing a solution for the pumping of acids can be especially challenging, even for common compounds such as sulphuric acid, hydrochloric acid and nitric acid. Not only do different acids often require different pump materials, but the characteristics of acids can vary considerably depending on their concentration and/or temperature.

Many acids are extremely dangerous to handle, and so it is essential that the correct pump for the application is selected. Also, the raw materials used in the production of some acids can be especially challenging, such as molten sulphur.

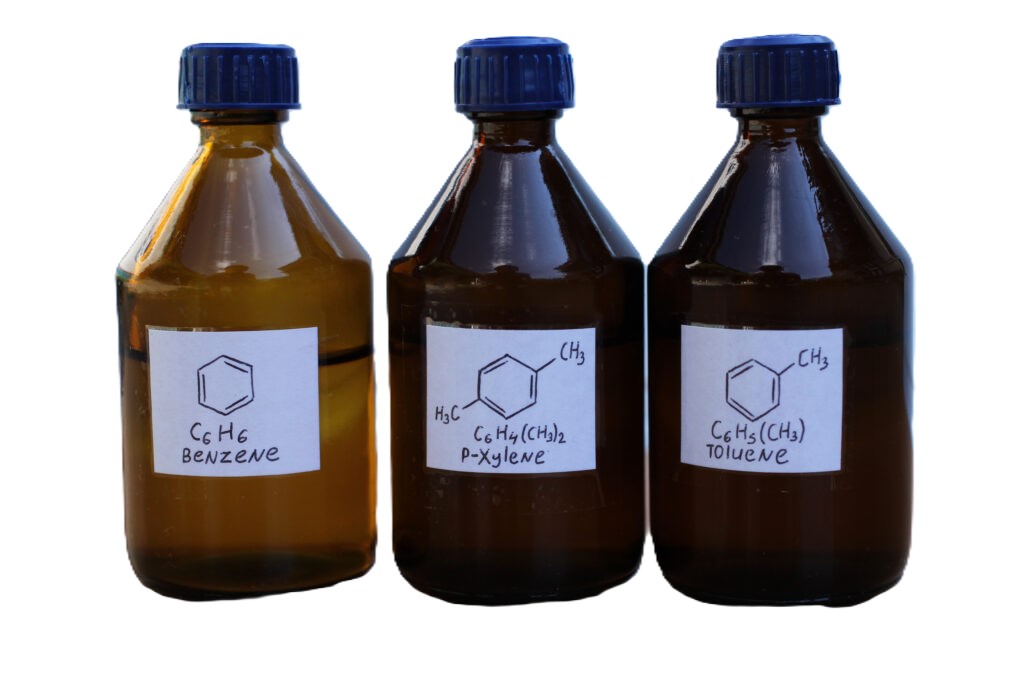

Solvents

Solvents are usually chemicals used to dissolve, suspend, and extract materials in a variety of applications, from pharmaceutical production, paints and inks, to cleaning products. Great care needs to be taken when selecting a pump for solvents as they can be highly flammable, toxic and corrosive.

There are a wide range of solvents, but some common ones are:

- Acetone

- Benzene

- Dichloromethane

- Ethanol

- Hexane

- Isopropyl alcohol

- Methanol

- Methyl ethyl ketone (MEK)

- Methylene chloride (MC)

- Paraffin

- Trichloroethylene

- Turpentine

All these solvents, and many more, have particular characteristics, and it should not be assumed that a pump suitable for one will be suitable for another.

Pumps for Polyurethane Foam Production

Polyurethane foam is a versatile material used in a wide range of applications, including seat cushions, home insulation, and heat-resistant shields for spacecraft. It is created through the reaction of polyols and isocyanates, often combined with various additives tailored to specific applications.

Selecting the right pump for polyurethane foam production presents unique challenges due to the nature of the chemicals involved. Many of these compounds are highly reactive with air, water, or other materials and can also be flammable. Therefore, careful consideration is essential when choosing a pump to ensure safety and reliability.

At Michael Smith Engineers Ltd, we have decades of experience in this field and have supplied pumps to all leading manufacturers of polyurethane foam insulation and related products.

Common Chemicals in Polyurethane Foam Production:

- Dimethyl Malonate (DEM)

- Dimethyl Pyrazole (DMP)

- Detergents

- Hexamethylene Diisocyanate (HDI)

- Isophorone Diisocyanate (IPDI)

- Methylene Diphenyl Diisocyanate (MDI)

- Methylethyl Ketoxime (MEKO)

- Polyol

- Surfactants

- Resins

- Toluene Diisocyanate (TDI)

For more information on polyurethane foam production and related pumps, please see the link below:

Pumps for Isocyanates & polyols

Frequently Asked Questions

What is a chemical pump?

A chemical pump is designed to safely handle, transfer, and dose corrosive or hazardous chemicals, including acids, alkalis, and solvents, without causing damage to itself or risking leaks.

What types of chemical pumps are available?

We have a range of chemical pumps including magnetic drive, air-operated double diaphragm (AODD), centrifugal and peristaltic pumps, each suited to different requirements and chemical compatibilities.

How do I choose the right pump for my industry or application?

Selecting the right pump depends on the type of chemical, flow rate, required pressure, and application environment. Contact our engineers for tailored advice based on your specific process requirements.

Can chemical pumps handle a wide range of corrosive chemicals safely?

Yes, chemical pumps are built with materials that are resistant to corrosion, such as PTFE, PVDF, or stainless steel to safely transfer aggressive chemicals and maintain operational safety.

Do you provide support and servicing for chemical pumps?

Yes, we offer expert technical support, after-sales servicing, and spares for the chemical pumps we supply to ensure reliability and extend pump life.