We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

A guide to to most common pump problems

This guide provides a number of checklists that cover most problems.

Before continuing, think about the way the pump is being used:

- Have the operating conditions changed?

- Is the pump running at the correct speed?

- Has the pumped fluid changed recently?

- Does the process fluid still match the original specification?

- Does it contain more abrasive materials?

- Is it more corrosive?

- Are the pump’s wetted parts chemically compatible?

90% of issues occur because of a problem on the suction side of the pump. Check the supply and suction-side pipework including valves, filters and strainers.

What are the common problems with pumps?

The pump won't start!

The pump isn't priming!

There is no flow/the flow is too low!

The pressure is not correct!

The pump isn’t running smoothly!

There is excessive wear!

The pump discharge is pulsating/intermittent

Problem not covered here?

Please contact us for assistance. However, we are only able to provide assistance for pumps from manufacturers we represent, or have represented in the past.

Glossary

The following articles provide explanations about some of the terms used in this Troubleshooting Guide:

Checklists

A pump motor generally fails to start because of electrical problems.

| Possible cause | Solution |

| Power failure | Check all power supplies and switches |

| Blown fuse | Check fuses on the motor and power supplies |

| Jammed coupling or motor | Verify coupling, motor and other drive equipment |

| Motor power supply problem | Check electrical connections and motor wiring |

Pump won’t turn / motor stalls

A motor may start but be unable to turn the pump if it has not been used for some time, if the pump has not been primed or if the load is too high, due to a high viscosity fluid or trapped solids.

| Possible cause | Solution |

| Liquid temperature higher than expected | Increases in temperature much beyond what the pump was specified to handle can fail seal elastomers, cause pins and bushings to lose their interference fits, or seize the pump. |

| Viscosity higher than expected |

Rotor and shaft materials, seals, and clearances are viscosity limited and may cause failures if not checked and adjusted. Viscosity increases may stall or damage the drive if not properly sized. Viscosity increases can also cause NPSH problems (watch for cold startups). |

| Overtightened packing gland | Packing requires some weeping for lubrication. |

| Pump running too fast for application | Increases in speed increase the pump’s NPSH requirement and line losses on both sides of the pump. This will also increase the power requirement. |

| Pump jammed | Lubricate as necessary and prime if required. |

| Diaphragm pumps only | |

| Blocked diaphragm chamber | Remove blockage |

| Air valve assembly malfunction/seizured | Check all seals, clean & lubricate |

| Clogged fluid line |

Clean line. Increase line diameter |

| Air connected to exhaust |

Check connections |

If the pump appears to be operating but there is no discharge flow, there is likely to be a problem with the supply, a blockage or closed valve, or the pump has lost its prime.

|

Possible cause |

Solution |

|

Air leak in suction piping (causes a cavitation-like noise.) Suction is below atmospheric pressure causing air leaks in pipework. |

Identify and eliminate air leaks. |

|

Vortex forming in supply tank, swirling liquid, reducing level at supply pipe and allowing air to enter pipe. |

Raise liquid level in supply tank; install vortex breaker. |

|

Suction pipe at bottom of tank |

Lift suction pipe away from bottom of the tank, cut pipe end at angle. |

|

Suction pipe too small or too long |

Use larger diameter pipe, minimise length and number of restrictions and elbows. |

|

Pump housing not filled with priming fluid/pump not primed |

Reprime pump. |

|

Suction pipework contains high spots causing trapped air pockets |

Flush lines until liquid flows free of air. Install vent valve in line at high spot. |

|

System head higher than anticipated |

Check pressure gauges and calculations. Increase pump speed. Centrifugal pumps: install larger impeller. |

|

Suction or discharge valve not open |

Check that all valves are open |

|

Suction lift too high or insufficient NPSH/NPIP |

Pump cavitating due to inadequate suction side pressure. Buildup in suction lines, partially closed inlet valves, dirty strainers, or an increase in liquid viscosity are all potential causes. |

|

Clogged suction line or strainer or impeller vanes |

|

|

Viscosity or specific gravity too high |

|

|

Clogged discharge line |

Flush line through vent valve. |

|

Suction/discharge pump connections incorrect |

Check that the suction and discharge pipes have been connected to the right ports on the pump. |

|

Rotation incorrect |

Check the direction of shaft rotation and wiring connections. Centrifugal pumps: check impeller is mounted correctly. |

|

Pump speed too low |

Check motor frequency and voltage. |

|

Pump has run dry/supply tank empty/suction pipe not submerged |

Check level in supply tank and that suction pipe is submerged. Prime pump. Gear pumps that are frequently run dry will exhibit increased wear and seal problems. |

|

Bypass valve open |

Check bypass valve operation. |

|

Relief valve bypassing |

Adjust to higher pressure. |

|

Magnetic drives: magnets uncoupled

|

Decoupling can be caused by a broken shaft, a foreign object, solids accumulation, excessive motor power. Verify position of outer magnet. Check temperature and viscosity of fluid. Stronger magnetic coupling may be needed. |

|

Gear pumps only |

|

| Head not mounted correctly | Head must align with seal area, refer to manufacturer. |

| Gear clearances too high for liquid viscosity | Refer to manufacturer. Reduce clearances. |

| Blockage in internal relief valve. | Close discharge valve to flush line through bypass valve. |

Low flow

A reduction in flow is normally accompanied by a drop in pressure so please also refer to the next checklist. Flow loss may occur because a portion of the flow is being diverted by a relief valve or bypass valve. The supply may be constrained or a change in conditions is causing cavitation. Wear of internal components could lead to pump slip whereby fluid leaks back to the suction side.

|

Possible cause |

Solution |

|

Air leak in suction piping (causes a cavitation-like noise.) Suction is below atmospheric pressure causing air leaks in pipework. |

Identify and eliminate air leaks. |

|

Vortex forming in supply tank, swirling liquid, reducing level at supply pipe and allowing air to enter pipe. |

Raise liquid level in supply tank; install vortex breaker. |

|

Suction or discharge valve not fully open |

Open valves fully. |

|

Clogged suction line or strainer or impeller vanes |

Flush lines, clean strainer. |

|

Incorrect relief valve setting |

Does the system incorporate a recirculation line? Could a relief valve be stuck open resulting in constant recirculation to the feed tank? Valve needs to be set to full-bypass pressure. A valve that is consistently bypassing will cause lower than expected capacity and a heat rise over time. |

|

Pump speed too low |

Increase driver speed or use larger pump. |

|

Pump worn or damaged |

Disassemble and inspect components. Replace worn parts. |

|

Slipping drive belt |

Check wear on any drive belts |

|

Rotation incorrect |

Check the direction of shaft rotation and wiring connections. Centrifugal pumps: check impeller is mounted correctly. |

|

Worn or blocked spray nozzles |

Check spray nozzles for wear or contamination |

|

Open or leaking bypass valve |

Check bypass valve is closed. |

|

Pump cavitating |

Are all valves on the suction side fully open during pump operation? Is there a filter prior to the pump? If so, could it have blocked? Operating outside without trace heating may lead to increased product viscosity in the winter months, and hence an increase in suction line frictional losses. Insufficient NPSHa/NPIPa. Check pressure gauges and operating conditions. |

|

Gear pumps only |

|

|

Incorrect head placement (internal gear pumps) |

Check head place in relation to the crescent. |

|

Excessive wear |

Check pump clearances. |

|

Viscosity too high |

Rotor and shaft materials, seals, and clearances are viscosity limited and may cause failures if not checked and adjusted. Viscosity increases may stall or damage the drive if not properly sized. |

|

Diaphragm pumps only |

|

|

Loss of oil prime in cells |

Check oil level |

|

Ruptured diaphragm |

Check diaphragms |

Pump not developing sufficient pressure

A reduction in pressure generally coincides with a decrease in throughput so please also refer to the previous checklist. The pressure may also be lower if the resistance of the discharge side is reduced.

|

Possible cause |

Solution |

|

Air or gas entrained in liquid |

Flush lines until liquid flows free of air. Check for suction side leaks. Is suction line fully submerged in supply tank? |

|

Impeller diameter too small |

Check with manufacturer. |

|

System head lower than anticipated |

Check calculations. |

|

Motor speed too low or rotation incorrect |

Check correct speed and rotation direction with manufacturer. |

|

Bypass valve partially open |

Check bypass valve is functioning correctly |

|

Pump cavitating |

Improper suction or feed. Are all valves on the suction side fully open during pump operation? Is there a filter prior to the pump? If so, could it have blocked? Operating outside without trace heating may lead to increased product viscosity in the winter months, and hence an increase in suction line frictional losses. Insufficient NPSHa/NPIPa. Check pressure gauges and operating conditions. |

|

Gear pumps only |

|

|

Incorrect head placement (internal gear pumps) |

Check head place in relation to the crescent. |

| Excessive wear leading to pump slip | Check pump clearances. |

| Diaphragm pumps only | |

| Loss of oil prime in cells | Check oil level |

| Ruptured diaphragm |

Check diaphragms |

Pump develops too much pressure

High pressure generally indicates a blockage in the discharge line or that the pump is running too fast.

|

Possible cause |

Solution |

|

Discharge valve not open |

Check that discharge valve is fully open. |

|

Incorrect relief valve setting |

Valve should be set to full-bypass pressure. A valve that is consistently bypassing will cause lower than expected capacity and a heat rise over time. |

|

Worn or blocked spray nozzles |

Check spray nozzles for wear or contamination |

|

Viscosity higher than expected |

Viscosity increases can also cause NPSH problems. May also happen during cold startups. |

|

Pump running too fast for application |

Increases in speed increase the pump’s NPSH requirement and line losses on both sides of the pump. This will also increase the power requirement. |

Loss of suction is generally caused by problems with suction side pipework ranging from trivial causes such as blockages to more serious and potentially damaging issues such as cavitation. Most positive displacement pumps can self-prime but sometimes, especially if a pump has not been used for a long time, it is necessary to fill the pump or wet internal components to allow self priming.

|

Possible cause |

Solution |

|

Not primed correctly |

Reprime pump: ensure the pump housing is filled fully before starting pump. |

|

Foot valve required |

Low viscosity liquids require foot valve to maintain prime. |

|

Closed discharge valve |

Open all suction and discharge valves |

|

Leak in suction line |

Check pipework for leaks |

|

Suction pipe/foot valve not submerged |

Verify suction pipe is submerged |

|

Foot valve jammed |

Check operation and seating |

|

Lift exceeds pump ability |

Check suction head against pump specification |

|

Suction lift too high/insufficient NPSH/cavitation |

Specific gravity or local atmospheric pressure not accounted for in calculations Reassess suction head and NPSH calculations |

|

Mismatch of inner volute and impeller diameter |

Refer to manufacturer |

|

O-ring damage |

Chemical attack, embrittled, or cut O-ring |

|

Motor rotation incorrect |

Correct rotation when viewed from fan end is clockwise FT SP series |

|

Air or gas in liquid |

Pump pulling in air through a loose fitting or from the supply tank. Suction line not fully submerged. |

|

Foreign matter in impeller |

Has a filter recently been removed from the suction line? Is the process liquid dirty? Obtain max particle size and concentration. Could the pump have run dry or operated while cavitating causing pump components to break off? |

Pump primes slowly

Loss of suction is generally caused by problems with suction side pipework. Most positive displacement pumps can self-prime but sometimes, especially if a pump has not been used for a long time, it is necessary to fill the pump or wet internal components to allow self priming.

|

Possible cause |

Solution |

|

Closed or partially closed valve |

Open suction and discharge valves |

|

Partially blocked suction line or strainer or impeller vanes |

Flush lines, clean strainer. |

|

Suction pipe diameter too large |

Use narrower suction line |

|

Air leak in suction piping |

Pump pulling in air through a loose fitting or through vortexing in the supply tank. Suction pipe not fully submerged. |

Centrifugal pumps |

|

| Mismatch of inner volute and impeller diameter |

Replace impeller |

| Inner volute O-ring damaged | Chemical attack, embrittled, cut |

Pump is noisy / excessive vibration/pulsation

A noisy pump can be a sign of cavitation, a loss of suction or entrained gas in the pumped fluid. The discharge pressure and flow may also be reduced, fluctuating or pulsating. Mechanical causes include worn components, drive systems, or shaft misalignment.

|

Possible cause |

Solution |

|

Air leak in suction piping |

Pump pulling in air through a loose fitting or from the supply tank. Causes a cavitation-like noise. |

|

Pump cavitating |

Review suction piping layout. Reduce angles and tees and ensure straight pipe run of at least 5 diameters before suction flange. Are all valves on the suction side fully open during pump operation? Is there a filter prior to the pump? If so, could it have blocked? Operating outside without trace heating may lead to increased product viscosity in the winter months, and hence an increase in suction line frictional losses. Insufficient NPSHa/NPIPa. Check pressure gauges and operating conditions. Reduce flow rate to match design specification. Is flow too low, leading to suction recirculation? Install or increase bypass so pump can be operated at specification. |

|

Pump base not rigid |

Inspect fixing bolts and grout. |

|

Poor alignment |

Check motor, coupling and pump alignment. |

|

Motor or piping not properly secured |

Is the suction and discharge pipework fully supported to ensure that there are no excessive loads on the pump casing? Is the adjoining pipe-work flexible or fixed? Was the unit realigned on site once installed? If the unit is long-coupled, has a flexible coupling been used? |

|

Foreign object in impeller |

Has a filter recently been removed from the suction line? Is the process liquid dirty? Obtain max particle size and concentration. Could the pump have run dry or operated while cavitation causing pump components to break off? |

|

Air lock |

This is a common issue when a suction feed line passes up and over the side of an IBC. Fully vent the system. |

|

Low bearing oil level/bearing failure |

Check oil level. Inspect bearing. |

|

Pump running too fast for application |

Increases in pump speed raise the pump’s NPSH requirement and line losses on both sides of the pump. This will also increase the power requirement. Check that the motor is running at the correct speed. |

|

Worn bearings |

Check pump and motor bearings and replace if necessary. |

|

Magnetic drives only: loose magnet/ drive magnet rubbing |

Check bearings on magnetic coupling for clearance between outer and inner magnets |

|

Magnetic drives only: boiling point exceeded in containment shell area: flashing |

Use temperature monitor on containment shell, Increase pressure in containment shell. Increase flow to reduce heat buildup. |

|

Diaphragm pumps only |

|

| Oil level low or incompatible with operating temperature |

Check oil level. Light weight oil needed for lower temperatures to prevent freezing. Check cells are primed correctly after diaphragm change. |

| Damaged diaphragm |

Elastomer incompatible with pumped fluid, puncture by foreign object, excess pressure, pump running too fast. Pump frozen. |

| Broken or worn valve spring | Cavitation

Foreign object in the pump Pump running too fast Spring/retainer material incompatible with fluid being pumped |

Pump runs hot

Overheating is generally a sign of a pump running too fast or that the pumped fluid is too hot or viscous. Wear may have reduced the clearances within the pump (valves, gears, bearings) leading to a build-up of frictional heat.

|

Possible cause |

Solution |

|

Incorrect relief valve setting |

Valve needs to be set to full-bypass pressure. A valve that is consistently bypassing will cause lower than expected capacity and a heat rise over time. |

|

Pump running too fast for application |

Increases in speed increase the pump’s NPSH requirement and line losses on both sides of the pump. This will also increase the power requirement. |

|

Internal circulation malfunctioning |

Consult manufacturer |

|

Packing too tight |

Loosen packing to allow greater lubrication of shaft. This may increase weeping. |

|

Bypass valve open |

Bypass rates in excess of 50% should be avoided. Pump action and recirculation causes temperature rise in pumped fluid supply. |

|

Magnetic drive only: flow lower than minimum required to cool containment shell area |

Ensure flow exceeds minimum required for cooling purposes. Install bypass line if process conditions require operation at low speeds. |

|

Magnetic drive only: magnets decoupled |

The maximum torque capability of the drive has been exceeded. This can occur during startup or through transient changes in load. Restart pump. |

The packing/seal is leaking

Before checking anything else, ensure that nothing has changed in the way the pump is being used. Have the operating conditions changed? Check that the O-rings and gaskets are compatible with the fluid and temperature. If anything has changed, the pump may require a different sealing system. Contact the manufacturer for advice if this is the case.

What causes leakage problems in centrifugal and gear pumps?

|

Observation |

Possible cause |

|

Packing starts leaking after a short period of operation |

Is there debris in the process fluid? Are there pressure transients during startup? Is the packing material suitable for operating conditions? Refer to manufacturer. Is the packing material suitable for stationary conditions/downtime? Refer to manufacturer. |

|

Packing extrudes into gland/bush throat |

Packing too soft. Are the end rings suitable (such as metal or reinforced PTFE)? Is the clearance too large? Has the packing gland been overtightened? Check torque meets specification. Packing requires some weeping for lubrication. |

|

Leakage occurs around the outside of the gland |

Has the packing been fitted correctly? Is the packing the correct size? Is there wear on the gland or stuffing box? |

|

Packing scored on outside, rotates with shaft |

Packing is wrong size or the stuffing box is worn |

|

Packing charred |

Dry-running, loss of lubrication |

What causes leakage problems in reciprocating pumps?

|

Observation |

Possible cause |

|

Seal leaks even when stationary |

Incorrect installation Damaged O-rings Seal faces not flat |

|

Seal leaks only when running |

Incorrect installation Eccentric shaft Excessive shaft runout Vibrations |

|

Seal leaks after a short period |

Debris in process fluid Transients during startup Seat or seal materials not suitable |

|

Seal leaks suddenly after satisfactory operation |

Cracked seals Bearing failure Loss of barrier fluid

|

Excessive wear of the pump internals

Some degree of wear is to be expected after prolonged operation, particularly if a pump is used with corrosive or abrasive feeds. Wear is primarily a function of pump speed and lifetime can be greatly enhanced by a reduction in pump speed.

|

Possible cause |

Solution |

|

Overtightened packing gland |

Packing requires some weeping for lubrication. |

|

Pump running too fast for application |

Wear due to abrasives increases exponentially with speed. |

|

Unexpected abrasives in fluid |

Install strainer in suction line. Reduce pump speed if possible or use larger pump running at lower speed. |

|

Extended dry running |

Install power sensor to stop pump from running excessively under dry conditions. |

|

Corrosion |

Construction materials incompatible with liquid. Check the specification with the manufacturer. |

|

Discharge pressure too high |

Increase discharge pipe diameter, decrease length |

|

Poor pump alignment |

Check motor, coupling and pump alignment. |

Excessive power consumption

An increase in power consumption could be due to mechanical or hydraulic problems. This could be due to increases in operating speed, pressure, flow or fluid viscosity. Mechanical causes could be wear or alignment issues.

|

Possible cause |

Solution |

|

Excessive flow |

Reduce pump speed |

|

Specific gravity or viscosity too high |

Heat fluid to reduce viscosity. Reduce pump speed. Increase drive horsepower. Shear sensitive fluids can become more viscous with pumping action and over time. |

|

Pump running too fast for application |

Increases in speed increase the pump’s NPSH requirement and line losses on both sides of the pump. This will also increase the power requirement. |

|

Mechanical problems |

Bearing wear. Shaft misalignment. Belt drives: poor pulley alignment. |

|

Gear pumps only |

|

| Gear clearances insufficient for viscosity and/or temperature |

Exchange for gears trimmed for operating conditions. |

| Rotating parts binding or worn | Disassemble and inspect components. Replace worn parts. |

Excessive leakage

Some degree of leakage is to be expected with shaft seals and bearings and is important for lubrication and cooling purposes. Excessive leaks are normally caused by loose or overtightened fittings or wear caused by abrasive solids in the pumped fluid.

|

Possible cause |

Solution |

|

Misalignment |

Shaft misalignment can cause premature wear of a pump’s seal, packing, shaft, and bearings. This can then lead to excessive leakage due to seal faces parting and becoming uneven. for more details on the importance of pump alignment see here. |

|

Inadequate pipework support |

Inadequately supported or misaligned pipework can put a strain on the pump casing, potentially causing deformation of the casing and/or shaft misalignment resulting in the seal faces parting or wearing out prematurely. |

|

Shaft seal failure |

Chemical or thermal incompatibility. Check O-rings and gaskets are compatible with fluid and temperature. Incorrect installation. Check seating of O-rings and gaskets. Torque bolts to specification. |

|

Overtightened packing gland |

Packing requires some weeping for lubrication but overtightening may cause overheating and damage to the packing or wear in the stuffing box. |

|

Pump port connections not properly seated |

Check O-rings and gaskets are compatible with fluid and temperature. Use Teflon tape or other sealant. |

|

Corrosion of pump housing |

Check compatibility of pump construction materials. Decrease temperature of fluid to reduce corrosion rate. Flush pump when not in use. Eliminate any contaminants that may accelerate corrosion wear. |

|

Diaphragm pumps only |

|

|

Loose connections |

Check oil draining piping/filler cap/valve plate and manifold bolts |

|

Is there fluid in the air exhaust? If so, possible causes are: |

|

|

Over-pressurisation |

O-ring forced out of groove. Warped manifold |

|

Ruptured diaphragm |

Elastomer incompatible with pumped fluid, puncture by foreign object, excess pressure, pump running too fast. |

| Outer plate unthreading | Tighten and re-torque |

Excessive Pulsations

Some variation in flow is to be expected with reciprocating pumps and this can be reduced by installing pulsation dampeners in the discharge line. With other pump types, such as centrifugal pumps, an irregular, pulsing discharge may be caused by cavitation, air in the system or by poor suction-side pipe layout.

|

Possible cause |

Solution |

|

Air in suction lines |

Pump pulling in air through a loose fitting or in a vortexing tank. Causes a cavitation-like noise. |

|

Oil level low |

Check oil level. Low level may cause loss of prime in hydraulic cell |

|

Pump cavitating |

Are all valves on the suction side fully open during pump operation? Is there a filter prior to the pump? If so, could it have blocked? Operating outside without trace heating may lead to increased product viscosity in the winter months, and hence an increase in suction line frictional losses. Insufficient NPSHa/NPIPa. Check pressure gauges and operating conditions. Reduce flow rate to match design specification. Is flow too low, leading to suction recirculation? Install or increase bypass so pump can be operated at specification. |

|

Water hammer |

Normally caused by valve closing too quickly. Check valve operation. Consider installing an accumulator tank or pulsation dampener in the discharge line to dampen pulsations. |

|

Poor suction-side pipe layout |

Review suction-side piping. Reduce angles and tees and ensure straight pipe run of at least 5 diameters before suction flange. |

|

Diaphragm pumps only |

|

| Damaged diaphragm |

Elastomer incompatible with pumped fluid, puncture by foreign object, excess pressure, pump running too fast. |

| Broken or worn valve spring | Can be caused by cavitation, foreign object in the pump, corrosion, pump running too fast. |

| Reciprocating pumps only | |

| Some degree of pulsation is to be expected with diaphragm pumps and other types of reciprocating pumps. If this becomes excessive, consider installing a pulsation dampener in the discharge line. |

Intermittent flow

Intermittent flow may result from a partial blockage in the system or by pump components, such as seals, slipping due to wear, component failure or over-lubrication.

|

Possible cause |

Solution |

|

Over lubrication |

Remove air connection into pump, degrease, reconnect and run until clear. |

|

Obstruction |

Clear obstruction, check ball valve seating |

|

Shaft seal failure |

Replace seals |

|

Diaphragm pumps only |

|

| Moisture in air valve |

Inspect valve for moisture and dry if necessary. Install air dryer. |

| Air valve system failure | Check all seals |

Getting more help

Before you call…

Make a note of the full duty details and clarify that the pump is operating within its specification. In particular, record anything that has changed since the pump was last performing satisfactorily.

- Can you supply photos or a video of the installation?

- How long has the pump run before the problems started happening?

- Is the pump run on any cleaning cycle? If so list the relevant details: liquid, temperature, speed and pressure.

- How long has the pump been installed?

- How long since it was last serviced?

Contacting Michael Smith Engineers Ltd

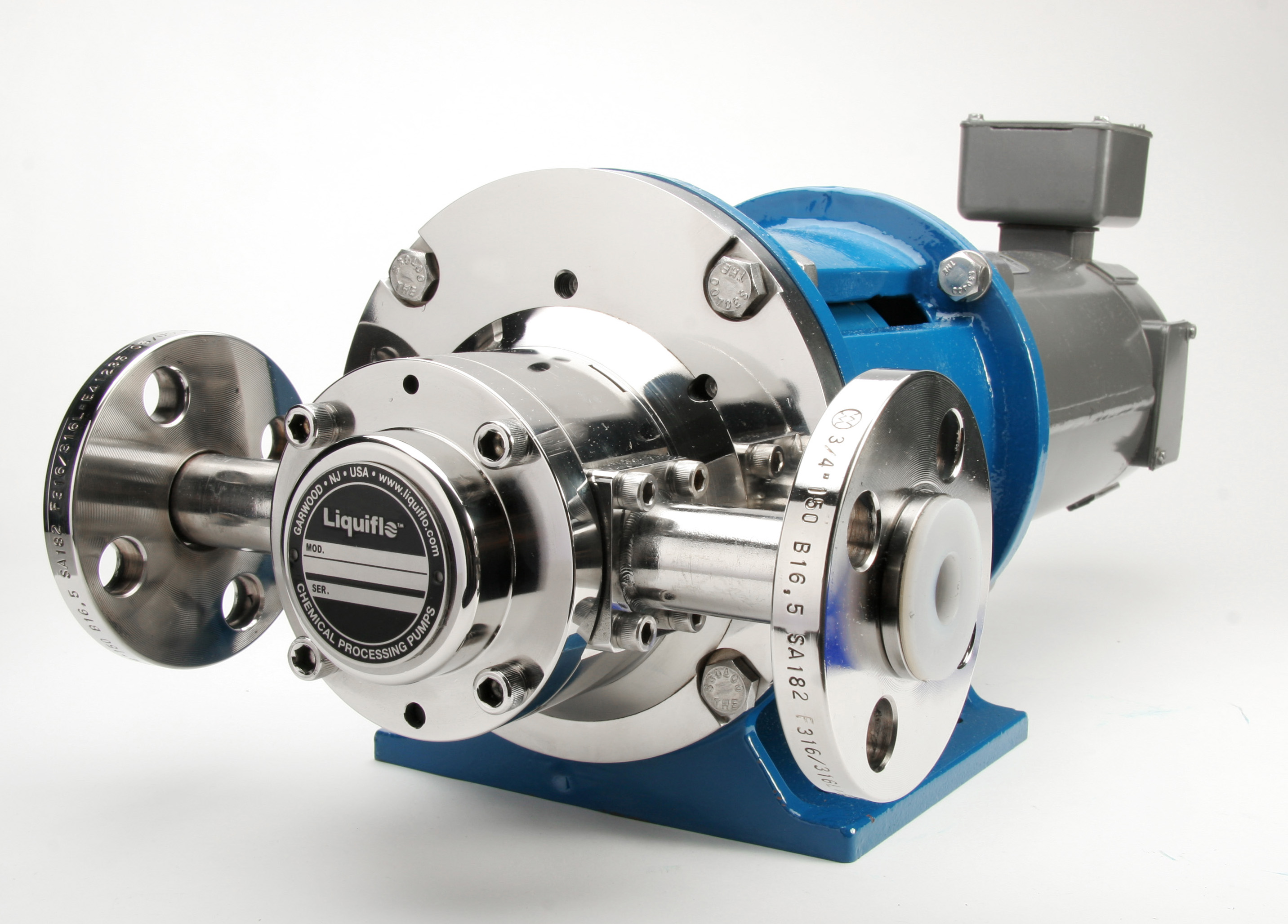

Michael Smith Engineers Ltd provides representation in the UK for specialist pump manufacturers, with particular emphasis on sealless leak-free pump technology.

For general advice please contact us: https://www.michael-smith-engineers.co.uk/contact-us

We have experience of pumping many hard-to-handle liquids including acids, bases, organic liquids, solvents, inorganic liquids, slurries, volatile liquids, corrosives, abrasive liquids, non-lubricating liquids, liquids with entrained gases and flammable liquids.

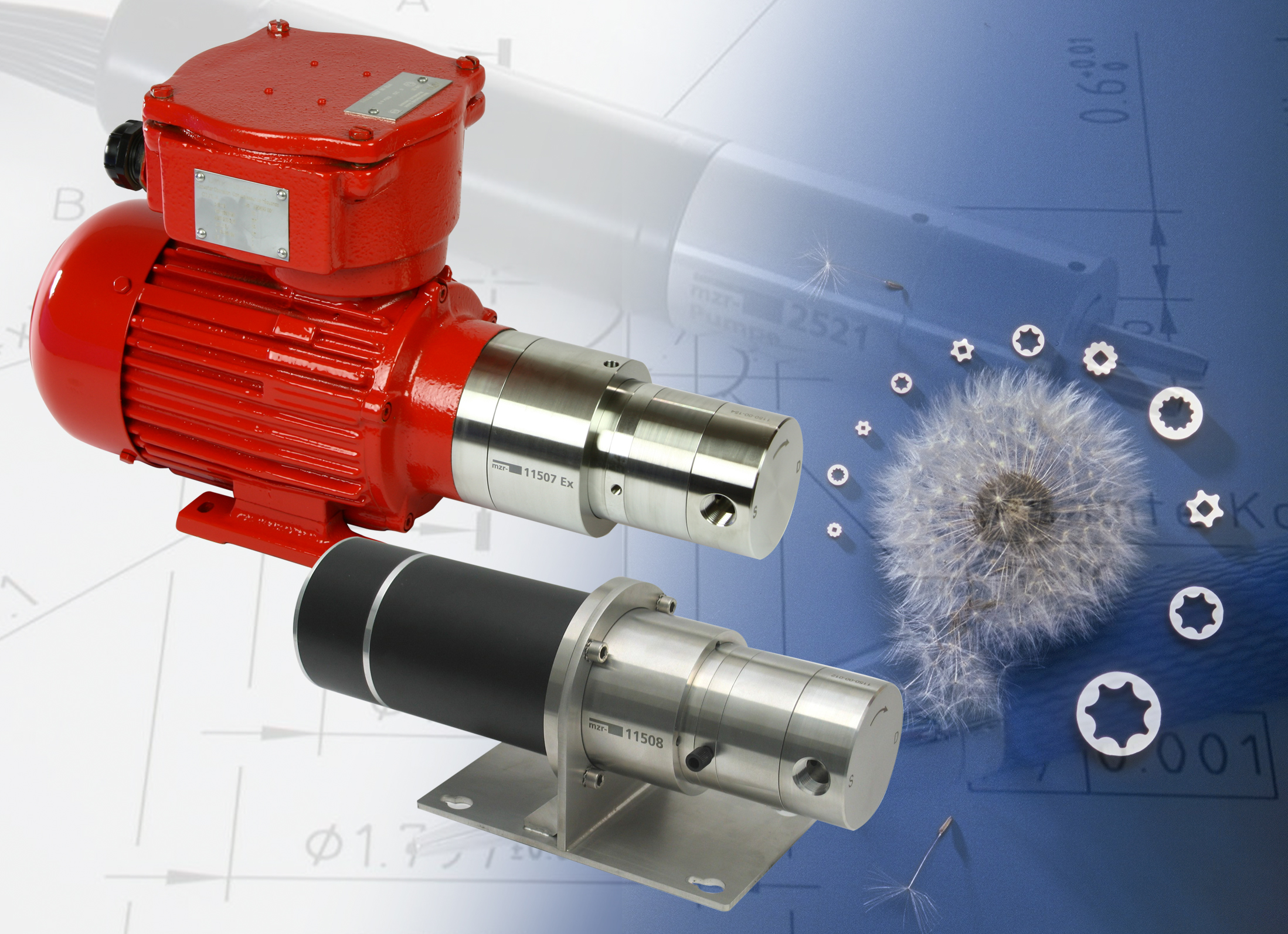

We are able to provide a wide range of drive options for the various ranges we represent including single phase and three phase motors, inverter control, DC motors, air motors, ATEX approved drives and manual and automatic variable speed units.

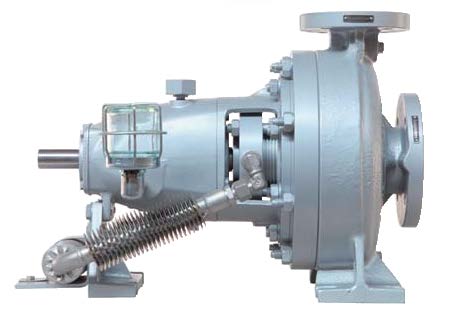

As well as supplying a complete range of specialist pumps and drives, we also offer a comprehensive range of accessories including filters, relief and loading valves, flow meters and tubing to complement the different types of pumps.