We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

Pump Case Studies

Real-World Pump Solutions by Michael Smith Engineers

Welcome to the Case Studies section of Michael Smith Engineers — where engineering excellence meets real-world application. Here you’ll find detailed stories showcasing how our pump solutions solve complex challenges across industries, from food processing and pharmaceuticals to chemicals, petrochemicals, scientific facilities and beyond. Each case study highlights our technical expertise, extensive experience, and commitment to reliability, demonstrating how we partner with clients to deliver efficient, effective, and long-lasting pumping systems.

Key Sectors

Chemicals |

Energy |

Food & Beverage |

Pharmaceutical |

Petrochemical |

Industrial |

Chemicals

Chemical transfer applications demand pumps engineered to withstand aggressive, corrosive, and often hazardous media. Our chemical pump range includes magnetically driven and mechanically sealed centrifugal pumps, sealless diaphragm pumps, and precision metering pumps, each designed with materials such as PTFE, PVDF, and high-alloy stainless steels to ensure maximum chemical compatibility. By eliminating leakage paths and minimising maintenance requirements, these pumps provide safe, reliable handling of acids, alkalis, solvents, and other challenging fluids across both laboratory and process environments.

- Hydrochloric acid transfer pump at a chemical manufacturer

- Self-priming pump for lifting hydrochloric acid from underground tank

- Bund emptying pump for acidic waste water

- Centrifugal pump for transferring distillates between storage tanks and road tankers

- ATEX Centrifugal pumps for acetone transfer

- Circulation pump for acid/copper sulphate solution

- Potassium hydroxide road tanker loading pump

- Sodium chlorate transfer pump

- Sodium hydroxide transfer pump

- Acid effluent transfer pump

- Chemical etching liquids transfer in harsh environment

- Hazardous chemical transfer in acid etching process

- Contaminated wastewater transfer in hazardous area

- Seal-less centrifugal pump for sodium hydroxide transfer

- Magnet drive side channel pump for hazardous methyl acrylic transfer

- Magnetically coupled centrifugal pumps for aggressive chemical handling in an industrial gas cleaning system

- Centrifugal pump for high temperature oil transfer

- Chemical transfer magnet drive pump for use in the plastic industry

- Magnetically coupled centrifugal pump for pumping sodium hypochlorite at a water treatment facility

- Caustic transfer magnet drive pump for use at a metal foundry facility

- Diaphragm pump for transfer of toluene

- Magnetic drive chemical transfer gear pumps

- Magnetically coupled pump for the transfer of a chemical used in the water treatment industry

- Seal-less gear pump for hydrogen peroxide transfer

- Sealless pump for chemical transfer at a UK cleaning product manufacturer

Energy

Energy sector processes place high demands on pumping equipment, requiring robust designs capable of operating under extreme temperatures, pressures, and continuous duty cycles. Our pumps for energy applications include sealless magnetic drive centrifugal pumps, high-pressure diaphragm pumps, and precision dosing systems engineered to handle heat transfer fluids, hydrocarbons, additives, and other process-critical media. Constructed from advanced alloys and engineered plastics, these pumps deliver leak-free performance, high chemical resistance, and long service life, making them ideally suited to power generation, oil and gas, and renewable energy operations where reliability and efficiency are paramount.

- AdBlue (DEF) road tanker unloading pump

- De-ionised water pump for electrolysers in green hydrogen production

- Hydrochloric acid transfer on offshore application

- Sodium chloride electrolysis circulation pump

- High-pressure seal-less diaphragm pump for green hydrogen production

- Seal-less centrifugal pump for de-ionised water circulation in hydrogen production

- Metering pump for application in the green hydrogen sector dosing de-ionised water and methanol

- Internal gear pump for hot dielectric liquid transfer

- Potassium hydroxide pump supplied to a hydrogen production company for use in alkaline electrolysers

- Magnetically coupled gear pump for diesel exhaust fluid (AdBlue) transfer

- External gear pump supplied to hydrogen production industry for potassium hydroxide transfer

Food & Beverage

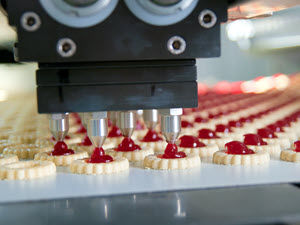

Pumping systems for the food and beverage industry must combine hygienic design with reliable performance to ensure product integrity and compliance with stringent sanitary standards. Our food and drink pumps include positive displacement, diaphragm, and centrifugal models constructed from FDA-compliant materials such as polished stainless steel and food-grade elastomers. With some units designed for clean-in-place (CIP) and sterilise-in-place (SIP) processes, these pumps minimise the risk of contamination while delivering gentle, low-shear transfer of shear-sensitive or viscous products. From dairy and brewing to flavourings and sauces, they provide safe, efficient, and repeatable handling of a wide range of consumable fluids.

- Magnetic drive centrifugal pumps for condensate in Scotch whisky production

- Drum pump for milk and whey transfer

- Hygienic lobe pump for pet food production

- Dosing pump for flavoured glycerols

- Pulse free metering pump for spraying flavourings

- Hot sunflower oil pump for potato crisp production

- Vegetable oil circulation pump at processing plant

- Hot vegetable oil transfer at food processing plant

- Hygienic lobe pumps for bakery machinery manufacturer

- Hygienic lobe pump for batter delivery at leading UK bakery

- Magnet drive pump for the production of culinary and cosmetic sea salt

- Hygienic twin screw pump for pet food production

- Air operated double diaphragm pump for water and rapeseed oil mix in the food industry

- Internal gear pump for UK producer of frozen foods

- Rotary lobe pump for viscous liquid transfer at prominent UK bakery

Industrial

Industrial processes demand versatile and robust pumping solutions capable of handling a wide spectrum of fluids, from abrasive slurries and viscous oils to solvents and cooling liquids. Our industrial pump range includes centrifugal, diaphragm, and gear pumps engineered for continuous duty, high reliability, and minimal maintenance in demanding environments. Constructed from durable materials such as cast iron, steel, stainless steel, and advanced polymers, these pumps provide excellent wear resistance and long service life. With options for ATEX compliance, sealless operation, and precise flow control, they are ideally suited to sectors including manufacturing, chemical processing, water treatment, and general plant engineering.

- Circulating pump for metal treatment solution

- Brine transfer pump for electrolytic cleaning process

- Circulation pump in industrial cleaning equipment

- Circulation pump for corrosion inhibitor

- Ferric chloride re-circulation pump for chemical etching of metal parts

- Acidic effluent transfer pump at aerospace parts manufacturer

- Hydrogen peroxide circulation pump

- Phosphoric acid circulation pump for rust removal system

- Sodium carbonate (soda ash) pump for pH correction

- Sodium hypochlorite recirculation for water treatment

- Sodium phosphate circulation for surface treatment process

- Centrifugal pump for chemical etching process

- Dosing cleaner and activator in coating systems

- Low pulsation gear pump for flow meter testing and calibration

- Precise dosing of liquids for the manufacture of spirit levels

- Grease dispensing onto furniture hinges

- Isocyanate and polyol dosing for polyurethane foam production

- Controlled filling of ballpoint pen refills

- Extrusion of polymers and pre-polymer melts

- Dosing of silicone gel for airbag production

- Dispensing silicone oil for watch gears and stepper motors

- Dispensing of coloured lacquer in spark plug production

- Dosing UV-curing adhesive for optical lens production

- Gearbox oil transfer gear pump at UK gearbox manufacturer

- Recirculation of raw water in a government research application

- Hygienic lobe pump for triethylene glycol transfer

- Internal gear pump for silicone oil delivery

- External gear pump for pumping lubicant connected to a feed vessell under full vacuum

- High viscosity liquid handling using an internal gear pump

Petrochemical

Pumps used in petrochemical processes must deliver safe, often leak-free, and continuous operation when handling hydrocarbons, solvents, and other hazardous or flammable fluids. Our petrochemical pump range includes sealless magnetic drive and mechanically sealed centrifugal pumps, high-pressure diaphragm pumps, and gear pumps designed to withstand aggressive chemicals, high temperatures, and demanding duty cycles. Available in standard metallic options such as cast iron, steel and stainless steel, alongside corrosion-resistant alloys, engineered plastics, and elastomers selected for hydrocarbon compatibility, these pumps ensure compliance with ATEX and industry safety standards. With options for precise flow control and low-maintenance operation, they provide reliable performance across refining, chemical processing, and downstream petrochemical applications. We also offer a range of API compliant pumps for the most stringent petrochemical requirements on oil rigs, refineries, and remore locations.

- Self-priming pumps for Jet A1 fuel

- Barrel emptying pump for aviation fuel dye

- Liquid carbon dioxide re-circulation

- External gear pumps for refinery fuel additive system

- Centrifugal and side channel pumps for jet fuel transfer at major UK fuel terminal

- Internal gear pump for fuel system at an oil terminal

- Self-priming vertical side channel pump for diesel transfer at an airfield

- External gear pump for kerosene transfer into an incinerator

Pharmaceutical

Pharmaceutical manufacturing requires pumps that combine precision, hygiene, and compliance with stringent regulatory standards. Our pharmaceutical pump range includes twin-screw, rotary lobe, diaphragm and centrifugal pumps designed for contamination-free transfer of active ingredients, buffer solutions, and sterile media. Constructed from FDA- and USP Class VI–compliant materials such as electropolished stainless steel and biocompatible elastomers, these pumps support clean-in-place (CIP) and sterilise-in-place (SIP) procedures to maintain aseptic conditions. With accurate flow control, low-shear handling, and validation-ready documentation, they deliver reliable performance in applications ranging from laboratory-scale production to full-scale pharmaceutical processing.

- Dilute acetic acid transfer pump for medical supplies production

- Continuous process pump for pharmaceutical ingredients

- Precision dosing of diols (glycols) for pharmaceutical R&D

- Dosing of lubricating oil for glass syringe manufacture

- Dosing of multiple liquids for Flow Chemistry application

- CIP recirculation for pharmaceutical manufacturer

- Hygienic side channel pump for ultra-pure water injection

- Magnetically coupled jacketed gear pump for water / ethylene glycol mix

- Multistage centrifugal pump for chemical transfer

- Repair of hygienic lobe pump for pumping egg protein at a pharmaceutical company

- Abrasive pharmaceutical waste transfer